TurboFil offers solutions for small parts, medical devices, and o-ring assembly. These solutions can be integrated into existing systems allowing for accurate and reliable results. Our engineers are experts in factory automation and can develop a turnkey system to fit your companies needs.

-

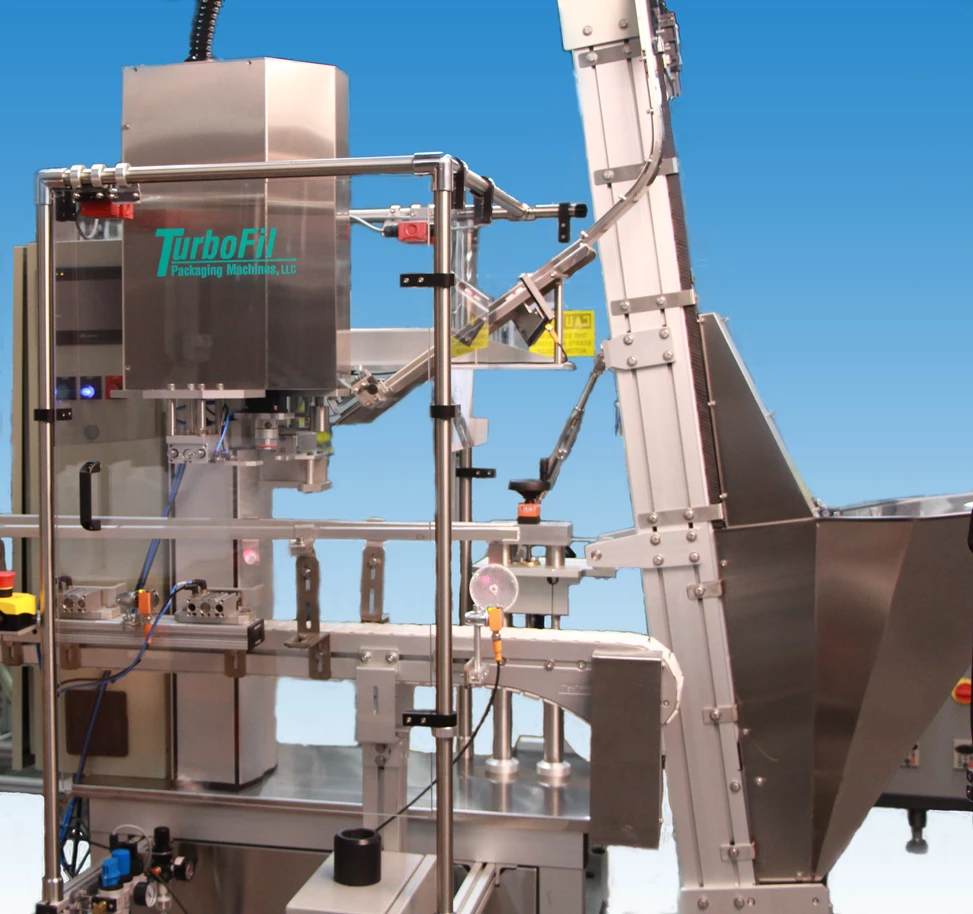

TurboFil’s Nail Polish Monoblock can be fully automated

-

Includes automatic bottle insertion with star wheel take-up, automatic BB dropping (shaking balls)

-

Automatic brush insertion

-

Automatic cap placement and torquer

-

-

For a wide range of bottle shapes and sizes

-

Accurate and gentle capping at speeds of up to 40 per minute

-

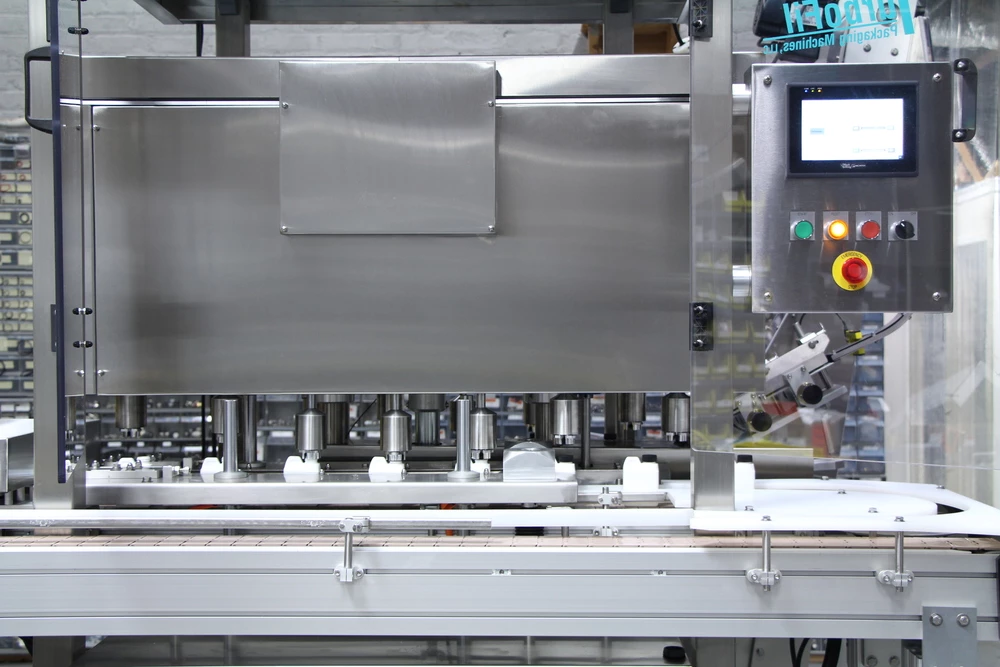

- High-precision filler for small vials and syringes

- Pump rated for a precision of 0.5% and accuracy of 1%

- Touchscreen user interface, allowing easy operation and maintenance

-

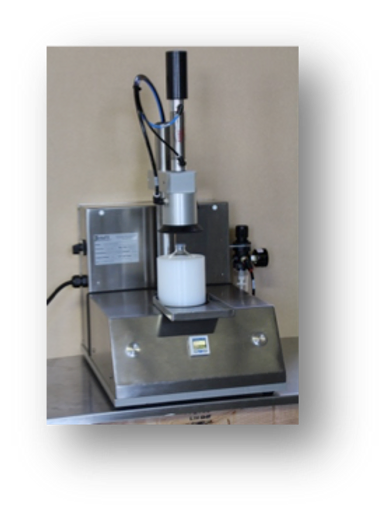

A simple versatile filler

-

Ideal for short runs

-

Motor for high viscosity liquids

-

Glass or stiff plastic containers

-

-

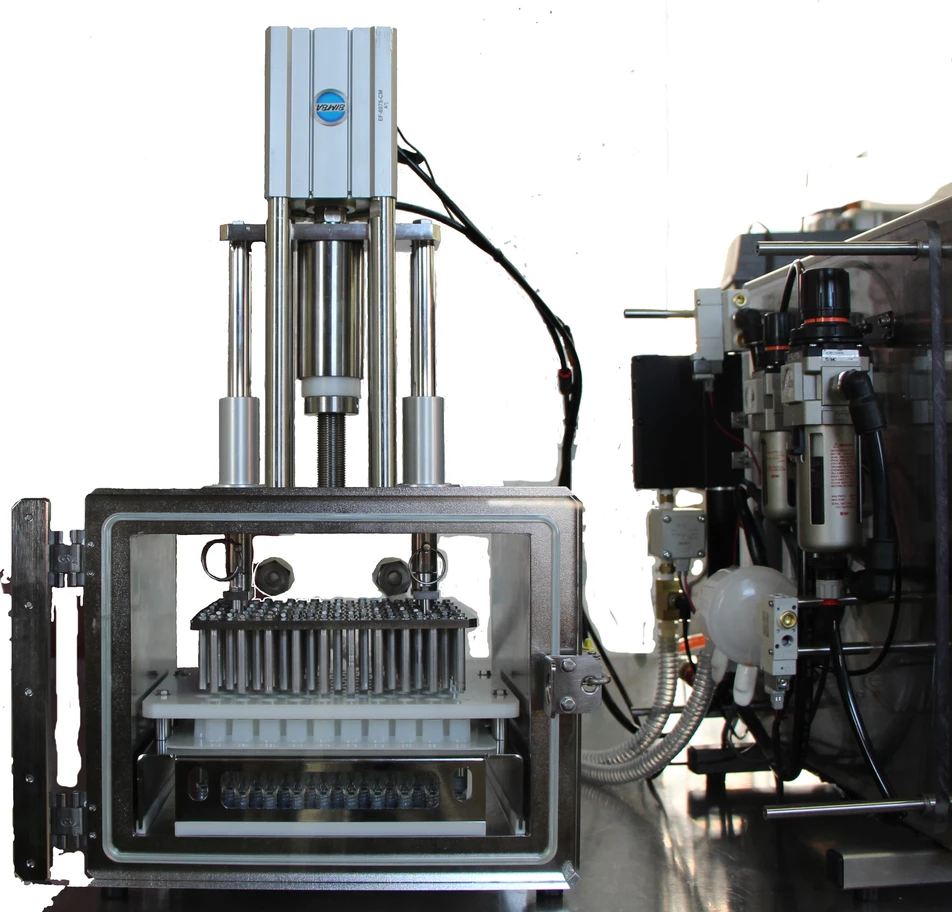

For inserting and seating stoppers or plunger rods into pre-filled syringes, vials or tubes

-