TurboFil’s Rotary Indexing Crimper can automatically apply and crimp all styles of caps onto vials at speeds of up to 50 bottles per minute.

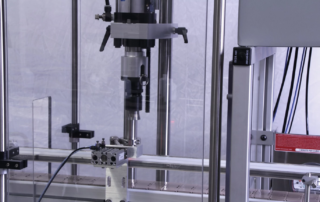

Vials with stoppers in place are fed to the IC-60s indexing dial via a conveyor or in feed tray. The caps are automatically fed and then pressed into position prior to crimping.

The IC-60s uses a collet style crimper to produce a clean and secure crimp, with easy set-up.

Because of TurboFil’s deep design expertise, this system can be fully customized to the requirements of your application

Features

-

Stand-alone unit with anodized aluminum frame and leveling feet can be attached to your existing conveyor or we can supply the conveyer.

-

Stainless steel mounting post with height adjustment

-

Photo-eye sensor detects position of the bottle to be crimped

-

Programmable Logic Control (PLC) with color touchscreen HMI

Specifications

-

Dimensions: 35” x 29” x 55”

-

Weight: Approximately 500 lbs

Speed: Up to 50 vials per minute

Options: Explosion-proof model optional

Key Benefits

- Very easy to use

-

Compact- small footprint

-

Cost effective

-

Easy changeover

-

Clean and secure crimp