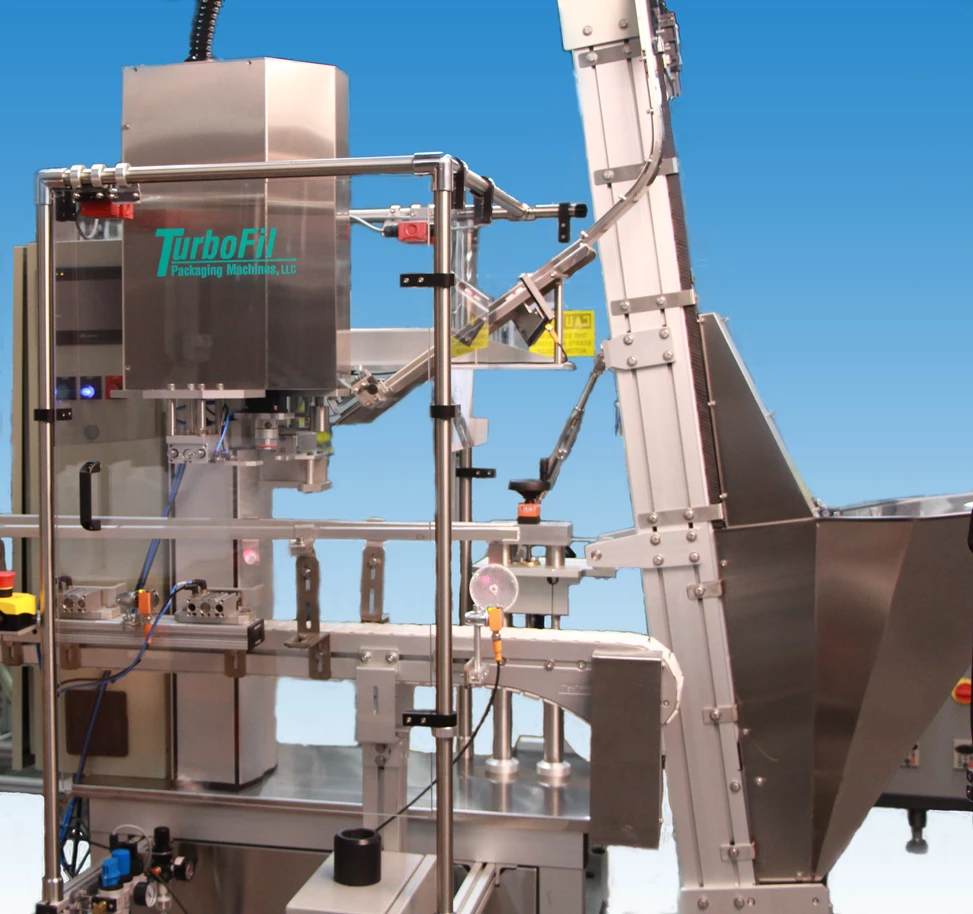

TurboFil’s new inline capper is the ideal marriage between cost-effective and servo-controlled capping.

This capper can be mounted on the customer’s existing conveyor (or we can supply a conveyor). It can be supplied as a fully automatic machine using a cap feeder or another option is for the operator to manually load the caps on a track.

Because of TurboFil’s deep design expertise, this system can be fully customized to the requirements of your application

Features

-

Speeds up to 30 bottles per minute

-

Excellent partner for Turbofil’s UniPuck Adjustable Puck Line

-

Automatic elevator feeder with track and sensors

-

1.5 cu. ft. hopper

-

Stainless steel discharge chute and cap applicator

-

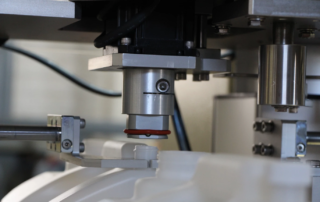

Pneumatic chuck

-

Cap tightener with servo control and adjustable torque

-

Servo controlled linear slide for the up and down motion.

-

Pneumatic gripper to grip the bottle.

-

Ability to control clockwise and counterclockwise rotation of chuck via HMI

Speed : Up to 30 bottles per minute

Specifications

-

Dimensions: 72” x 48” x 94” Other layouts are available

-

Weight: Approximately 400 lbs