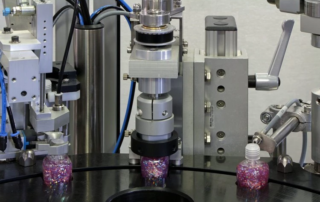

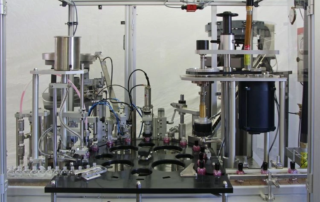

This is TurboFil’s fully automatic nail polish filling and assembly machine. It can operate at speeds of up to 55 bottles per minute (or up to 100 pieces per minute with dual-index capability).

This machine uses a positive displacement cam-driven piston pump with a cam driven diving fill nozzle. Vacuum suck back ensures esthetic fill level. It is very compact for minimum footprint and overall space saving.

Rapid changeover between colors (less than five minutes) is easily accomplished with minimal use of solvent.

For most standard components, changeover requires no tools and few change parts. The fully automatic version includes: automatic bottle insertion with star wheel take-up, automatic BB dropping (shaking balls), automatic brush insertion, automatic cap placement and torquer.

TurboFil’s Nail Polish Monoblock can also be ordered semi-automatic, with some functions replaced by manual operation (according to need).

Because of TurboFil’s deep design expertise, this system can be fully customized to the requirements of your application

Features

-

Container types: round, square, oval, rectangular, tapered, irregular

-

Closure types: brush, cap or brush cap unit, screw brush with press-on overcap

-

Cam driven fill station

-

Cam driven diving nozzle

-

Electric operated vacuum suck-back

-

Electric operated chuck type capper with adjustable torque clutch

-

Stainless steel and solvent resistant wetted components

-

Explosion proof controls and drives

-

Stainless steel sheathed top plate

-

UHMW star wheel and guide plates

-

Cost effective for enhanced productivity

Speed: up to 50 pieces per minute with single index, or 100 with dual index

Specifications

-

Power On-Off switch/circuit breaker.

-

Electric control box

-

7” Color Touchscreen HMI

-

PLC machine controller (Allen Bradley)

-

Ethernet capability for remote diagnostics