TurboFil offers solutions for small parts, medical devices, and o-ring assembly. These solutions can be integrated into existing systems allowing for accurate and reliable results. Our engineers are experts in factory automation and can develop a turnkey system to fit your companies needs.

-

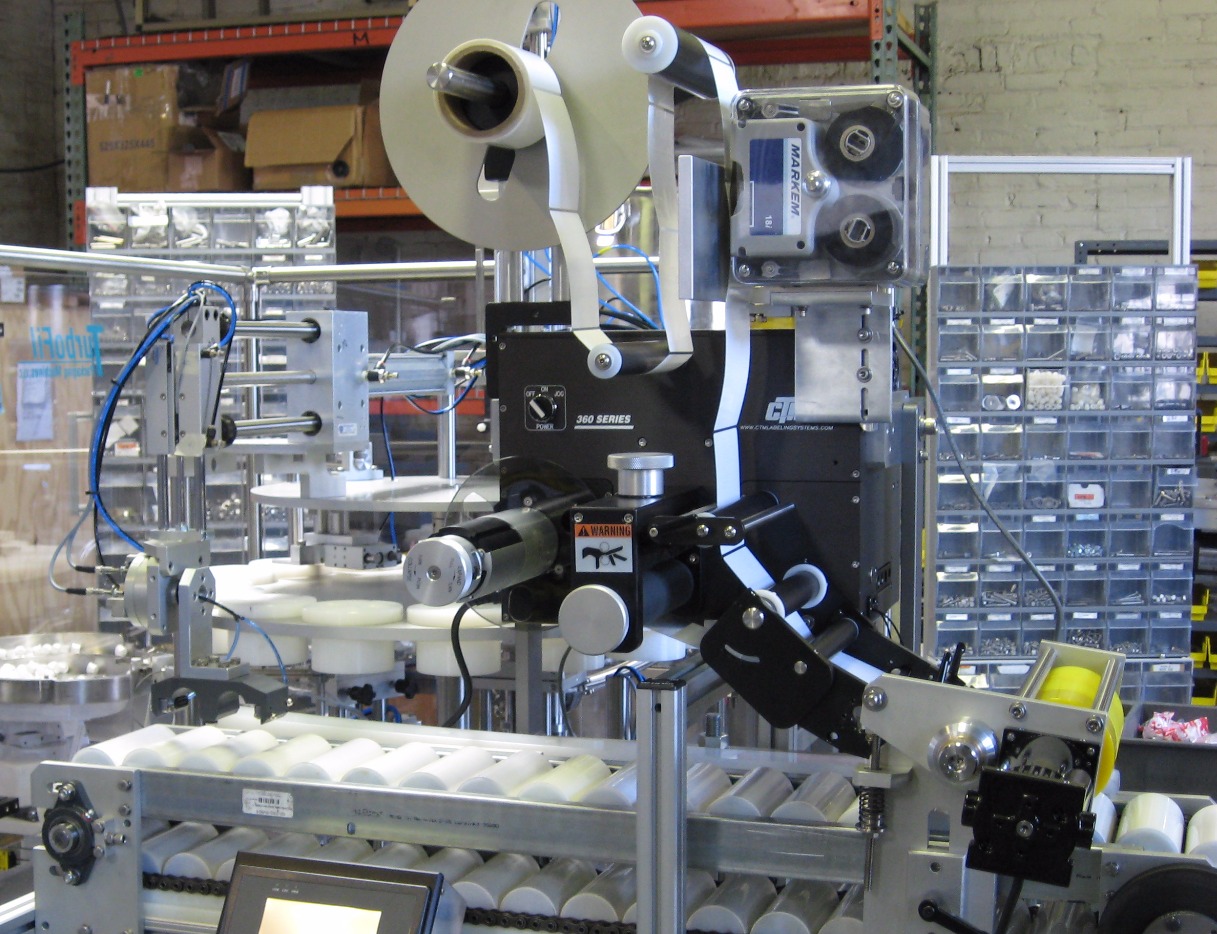

Standard web width up to 5″

-

Portable and lightweight table top unit

-

Label application activated by foot switch

-

-

Standard web width up to 5″

-

Portable and lightweight table top unit

-

Label application activated by foot switch

-

- 1:1 plastic dual chamber syringe

- 30 Syringes per minute

- Option for printer

-

For filling & assembly of UDS nasal systems from Aptar and others

-

80-100 PPM

-

Liquid filling accuracy +/- 0.5%

-

Suitable for aseptic environments

-

-

Workstation for inserting pistons or plungers into single or double barrel syringes (or cartridges)

-

-

Syringes filled through the tip

-

Liquid filling accuracy +/- 0.5%

-

Suck back nozzle design for drip free operation

-

Can be filled by either direct draw, a peristaltic pump or a piston pump

-

-

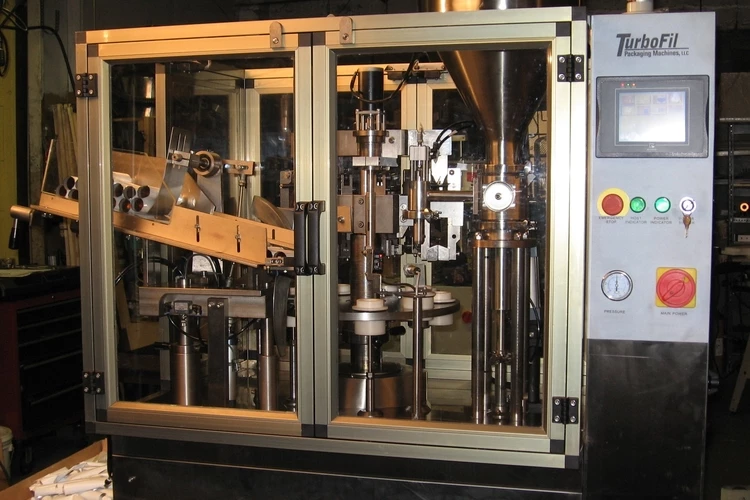

Models for metal and plastic tubes available

-

Up to 60ppm for metal tubes

-

Up to 40ppm for plastic tubes

-

-

The Perfume UniPuck Adjustable Puck line uses vacuum filling for fast level filling

-

The system allows for easy changeover with so many bottle sizes and shapes

-