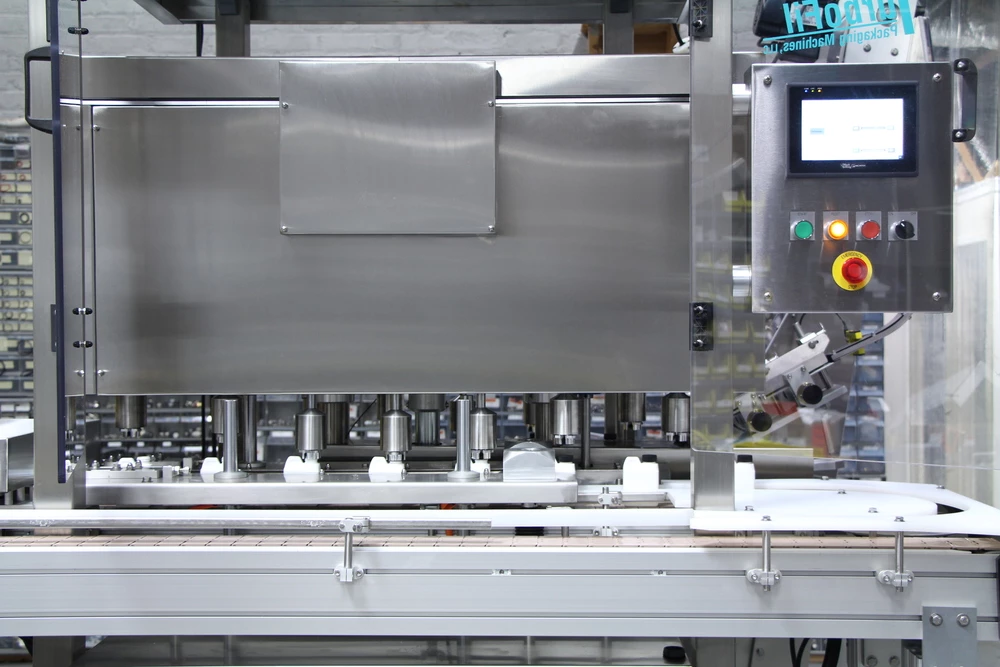

TurboFil’s Acrobat is a proud TurboFil innovation. It combines the benefits of flexibility and easy changeover of a spindle capper with the precise torque and reliable cap handling offered by chuck cappers…All at up to 80 bottles per minute.

Bottles enter the capper via parallel belts (like a spindle capper) and then the bottle is met by the cap held by the capper chuck. The cap is placed and precisely torqued. The system uses a positive three-jaw pneumatic gripper for gentle handling of the cap.

There are no change parts for different bottles. Simply adjust the distance between the belts and the height of the capper. Unique bottle shapes are easily accommodated. Cap changeover is also quick and easy. Just change the chucks (1 or 4 chucks depending on machine speed and model).

Because of TurboFil’s deep design expertise, this system can be fully customized to the requirements of your application

Features

-

Easy cap changeover

-

Results are reliable, accurate, and repeatable at any speed

-

Available in models suitable for hazardous environments

Speed : Up to 45 ppm for a single head unit, or 80 ppm for double head unit

Specifications

-

Dimensions: 100” x 50” x 90”

-

Weight: Approximately 700 lbs

Options

-

Electric push button height control

-

Crooked cap reject

-

No/low torque reject

-

Custom collets for unusual caps

-

Extended bottle and cap sizes

-

PC interface

-

Ethernet for remote diagnostics

-

Integrated elevator and bowl sorter with cap chute

-

Conveyors

-

Low level hopper indicator

-

Extended range of feeding hoppers

Key Benefits

-

Consistent and accurate applied torque

-

Easy changeover

-

Torque adjustment without stopping production