TurboFil offers solutions for small parts, medical devices, and o-ring assembly. These solutions can be integrated into existing systems allowing for accurate and reliable results. Our engineers are experts in factory automation and can develop a turnkey system to fit your companies needs.

- Two at a time syringe filling through the Tip

-

Automatic Capping

-

Small Footprint

-

Labeling and check weighing options available

-

Tail syringe filling and piston insertion

-

Automatic capping available

-

Single or dual barrel syringes

-

Speeds up to 45ppm

-

Accommodates very high viscosity materials

-

-

Clean room workstation for filling, capping and assembly

-

Semi-automated to pace operators

-

Intended for small to intermediate sized batches

-

-

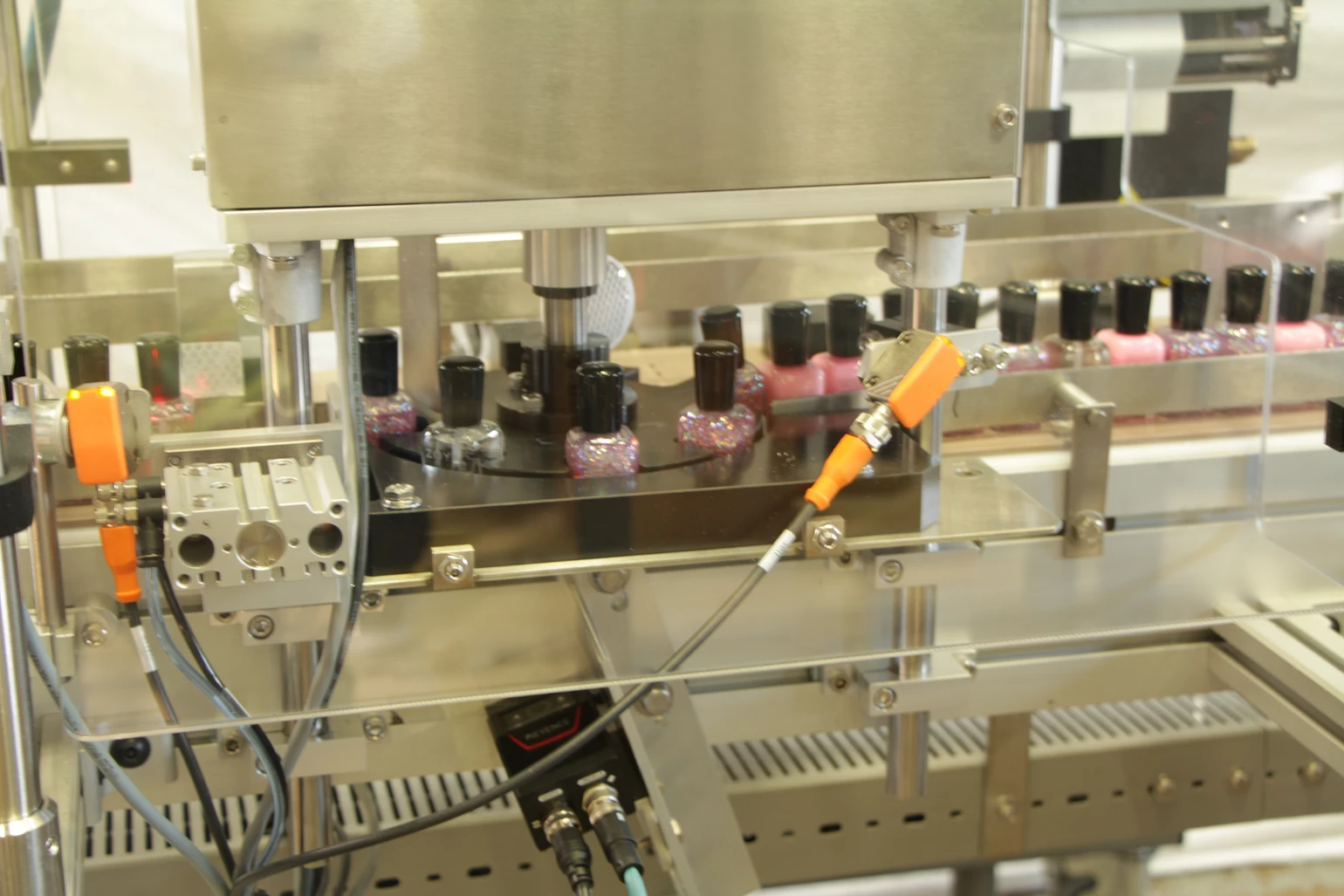

Accurate, easy-to-use filler for nail polish and other products

-

Suitable for glitters, micas and plain polish or gel

-

-

Compact machine

-

Automatically fills and caps or crimp closes

-

Great for small bottles or vials

-

-

Semi- or fully- automatic Monoblock includes bottle placing, filling

-

Wiper placing, and cap/ applicator placing and torquing

-

- For press on caps, collars and overcaps

-

Built on our linear format

-

Allows filling, capping and labeling of syringes on the same platform

-

-

In-line piston filling of nail polish with 2 to 8 nozzles

-

Suitable for glitters, micas and regular nail polish or gel

-