TurboFil offers a full line of pharmaceutical vial filling, crimping, capping, & stopper placement machines. Our vial filling & assembly machines can handle a range of production levels, we offer semi automatic for low volumes, progressing up to automatic machines for higher volumes.

Sterile and non-sterile vial filling is available with the capability of handling both low & high viscosity liquids.

We work directly with our customers to understand their existing vial filling & assembly process allowing us to identify any potential areas of improvement. All our machines are customizable, this enables us to match a vial filling system directly to a customers application.

Automatic Filling and Assembly

- Flexible system

- Filling, stoppering, and crimp capping vials

- Bottles ranging from 2ml to 100ml in size

- Versitrack is TurboFil’s most flexible system for filling and assembly

- Speeds up to 100bpm for a variety of formats

-

Clean room filler for nested syringes, vials and cartridge

-

Small to intermediate sized batches

-

-

For filling & assembly of UDS nasal systems from Aptar and others

-

80-100 PPM

-

Liquid filling accuracy +/- 0.5%

-

Suitable for aseptic environments

-

Semi-Automatic Filling

-

Clean room filler for nested syringes, vials and cartridge

-

Small to intermediate sized batches

-

-

For filling & assembly of UDS nasal systems from Aptar and others

-

80-100 PPM

-

Liquid filling accuracy +/- 0.5%

-

Suitable for aseptic environments

-

Crimping

- Flexible system

- Filling, stoppering, and crimp capping vials

- Bottles ranging from 2ml to 100ml in size

-

Clean room workstation for filling, capping and assembly

-

Semi-automated to pace operators

-

Intended for small to intermediate sized batches

-

-

For filling & assembly of UDS nasal systems from Aptar and others

-

80-100 PPM

-

Liquid filling accuracy +/- 0.5%

-

Suitable for aseptic environments

-

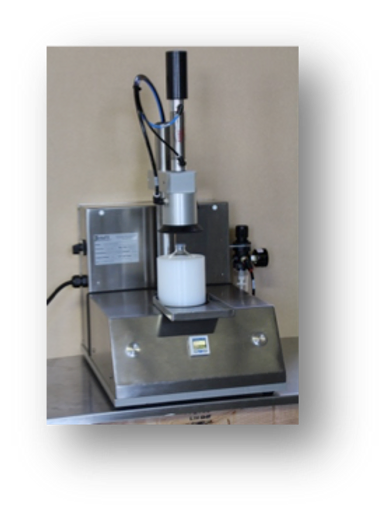

Screw Capping

- Flexible system

- Filling, stoppering, and crimp capping vials

- Bottles ranging from 2ml to 100ml in size

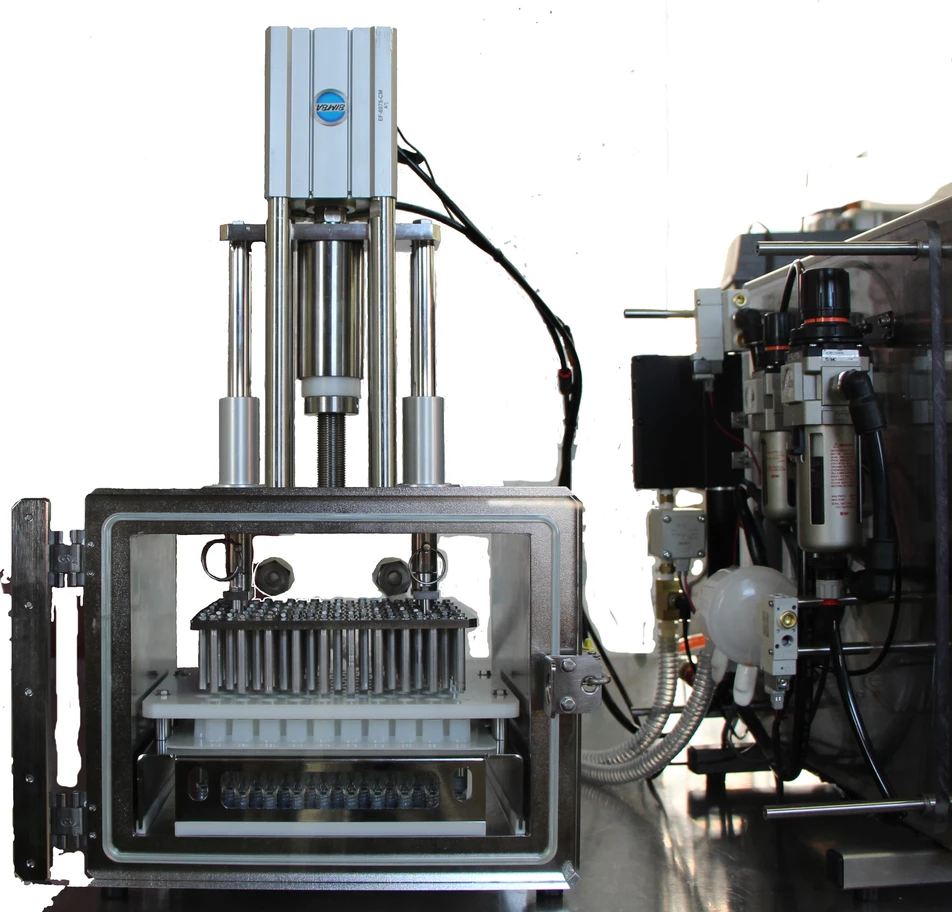

Stopper Placement

- Flexible system

- Filling, stoppering, and crimp capping vials

- Bottles ranging from 2ml to 100ml in size

-

For inserting and seating stoppers or plunger rods into pre-filled syringes, vials or tubes

-

-

Workstation for inserting pistons or plungers into single or double barrel syringes (or cartridges)

-

-

For filling & assembly of UDS nasal systems from Aptar and others

-

80-100 PPM

-

Liquid filling accuracy +/- 0.5%

-

Suitable for aseptic environments

-