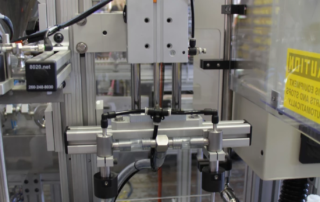

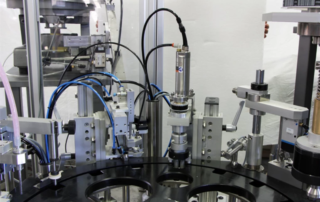

This is TurboFil’s fully automatic mascara / lip gloss filling and assembly machine. It features operation at speeds of up to 50 bottles per minute depending on the product to be filled. This TurboFil Monoblock is compact in size, with easy access to all stations for service or changeovers. It uses a positive displacement cam driven piston pump with a cam or servo motor driven bottom-up fill nozzle (drip-proof nozzle).

The fully automatic version includes bottle placing, filling, wiper placing, and cap / applicator placing and torquing. The machine is PLC controlled, with “no bottle…no fill” protection, and a reject chute for bad bottles. We offer an optional heated hopper with water / oil circulation system or a pressurized hopper with automatic electric or pneumatic supply pump control.

TurboFil’s Mascara / Lip Gloss Monoblock can also be ordered semi-automatic, with some functions replaced by manual operation (according to need).

Because of TurboFil’s deep design expertise, this system can be fully customized to the requirements of your application

Features

-

Container types: round, square, triangular or irregular

-

Closure types: wiper, brush / applicator, cap

-

Cam driven fill station

-

Cam or servo driven bottom up fill nozzle

-

Operator interface

-

Stainless steel and Teflon wetted components

-

Quick removal of wetted components for clean-up

-

Stainless steel sheathed top plate

-

Nickel plated dial plate

-

Delrin holding pucks

-

Optional touch screen

-

Cost effective for enhanced productivity

Speed : Up to 50 bottles per minute

Specifications

-

Stainless steel control box.

-

Power On-Off switch/circuit breaker.

-

Machine Stop and Start function key.

-

PLC machine controller (Allen Bradley)

-

7” Color touchscreen HMI (Maple Systems)

-

Syringe verification sensor.

-

Cap verification sensor

-

Emergency Stop switch.

-

Purge – Run mode switch.