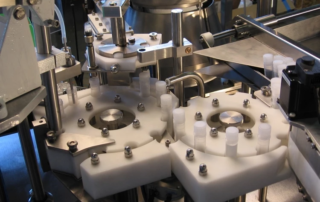

Filling and Assembly Monoblock for Small Bottles and Vials. This is TurboFil’s tabletop Minimonoblock, a compact machine that automatically fills and caps or crimp closes small bottles or vials.

It brings proven TurboFil technology to a new level with the most versatile machine available in this compact low profile format. Sophisticated, yet surprisingly clean and easy to operate, it avoids the need to move bottles between machines with conveyors.

TurboFil’s MiniMonoblock can be fitted with a variety of filling technologies to suit almost any small bottle or vial application. The bottles or vials are loaded into the infeed tray by the operator, automatically filled and closed by the machine and them discharged into an output tray for further processing. The machine is PLC controlled with no bottle…no fill, and no fill… no cap protection.

Because of TurboFil’s deep design expertise, this system can be fully customized to the requirements of your application

Features

-

Container types: glass or plastic bottles or vials

-

Closure types: screw caps or crimp tops

-

Cam driven fill station; option for servo driven

-

Filling options include piston, peristaltic, etc.

-

Operator interface: color touch screen

-

Stainless steel or ceramic wetted components

-

Quick removal of wetted components for clean-up / autoclaving

-

Stainless steel sheathed top tooling plate

-

Cost effective for enhanced productivity

-

Validation package available

Speed : 15 -40 per minute

Specifications

-

Dimensions : 64” x 66” x 60”

-

Weight: Approximately 500 lbs