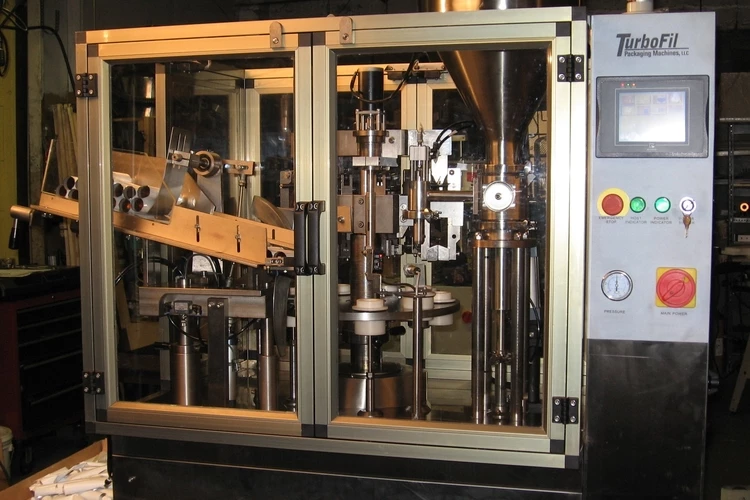

This is TurboFil’s Tube Filling and Sealing Monoblock. The various models can automatically fill and seal aluminum, plastic, and laminate tubes.

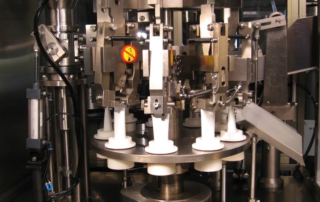

The fully automatic filling and assembly machine includes: tube placing, orientation, filling, sealing, and coding. It is PLC controlled with no tube..no fill protection

Because of TurboFil’s deep design expertise, this system can be fully customized to the requirements of your application

Features

-

Tube types: metal, plastic or laminate

-

Closure types: hot air / hot jaw, ultrasonic, double,

triple and saddle fold for metal tubes -

Cam-driven fill station

-

Touch screen interface

-

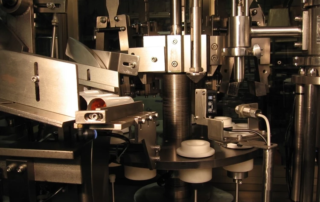

Stainless steel wetted components

-

Quick removal of wetted components for clean-up

-

Stainless steel sheathed top plate

-

Cost-effective for enhanced productivity

Specifications

Plastic Tube

-

Filling volume: 5-250ml or 50-500ml

-

Tube diameter: 10-50mm or 20-60mm

-

Tube height: Max. 210mm or Max. 250mm

-

Speed: Up to 40 tubes/minute.

Metal Tube

-

Filling range: 5-120 ml or 50-200 ml.

-

Tube height: 190 mm (max).

-

Tube diameter: 10-30 mm or 19-40 mm.

-

Speed: Up to 60 tubes/minute.

Both Models

-

Hopper size: 40L

-

Dimension: 1900 × 1000 × 1900 mm.

-

Weight: 900 kg.

-

Voltage: 220V 3phase

-

Air 15 CFM @ 90psi