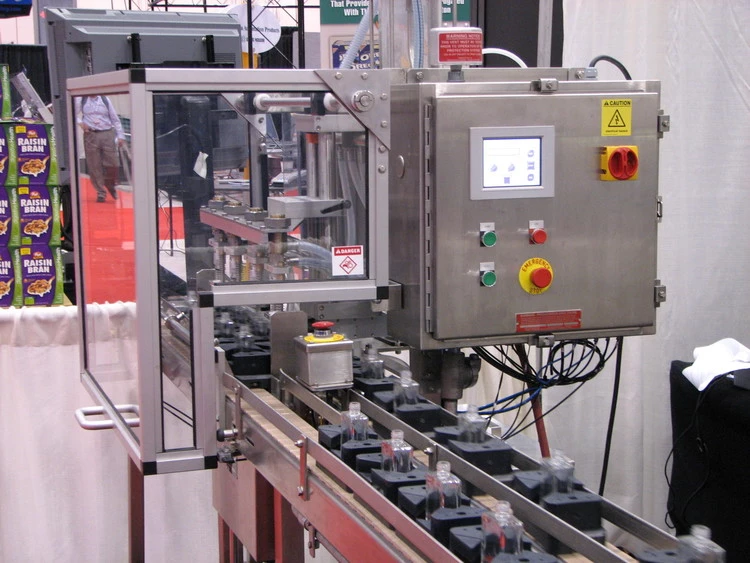

The TurboFil UniPuck® System is an Adjustable Puck Inline Filling System. Its breakthrough patented design makes it the most flexible filling and closing system available today.

This system uses a closed loop tabletop chain conveyor to move adjustable carrier pucks through a series of workstations to fill and close bottles.

-

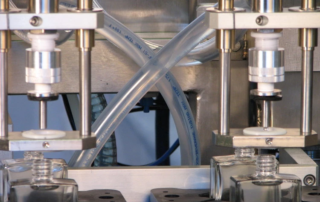

Filling systems are tailored to the application: vacuum for perfumes, piston for lotions and creams, peristaltic when required.

-

Quickly adjust pucks for almost any shape and size bottles means no change parts needed

-

No need to adjust guide rails allows for rapid changeover between bottles

-

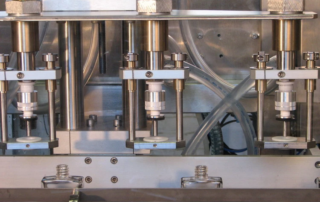

No need to adjust space between nozzles

-

Even unstable bottles are easily filled, crimped and capped

-

Pucks are quickly and easily adjustable with electric hand screwdriver

-

Large range of bottle, vial or jar sizes

-

Perfect for large or small runs

Because of TurboFil’s deep design expertise, this system can be fully customized to the requirements of your application

Features

-

Container types: glass or plastic

-

Closure types: screw cap, crimped cap or snap cap

-

Servo driven fill station

-

90 degree side transfer for filling on dead plate

-

Filling options include piston, peristaltic, etc.

-

Allen Bradley PLC

-

Operator interface: color touch screen

-

Stainless steel wetted components

-

Quick removal of wetted components for clean-up

-

Filler options include piston, vacuum, pressure and peristaltic

Speed : Up to 60 per minute