TurboFil offers solutions for small parts, medical devices, and o-ring assembly. These solutions can be integrated into existing systems allowing for accurate and reliable results. Our engineers are experts in factory automation and can develop a turnkey system to fit your companies needs.

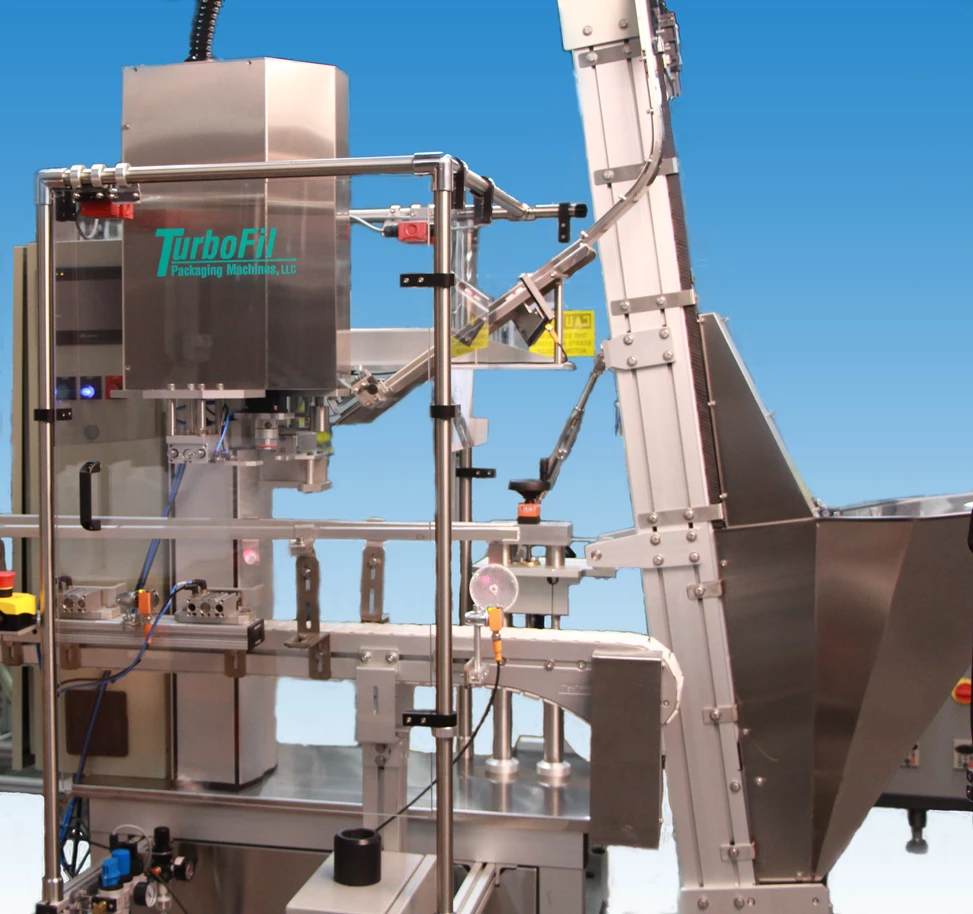

Function: High-speed monoblock system for fully automatic filling, brush/cap insertion, BB dropping, and torquing of nail polish bottles.

Container Compatibility: Supports round, square, oval, rectangular, tapered, and irregular bottle shapes with various closure types (brush, cap, brush-cap combo).

Output Capacity: Up to 55 bottles/min (single index) or up to 100 pieces/min (dual index)

Material Handling: Nail polish

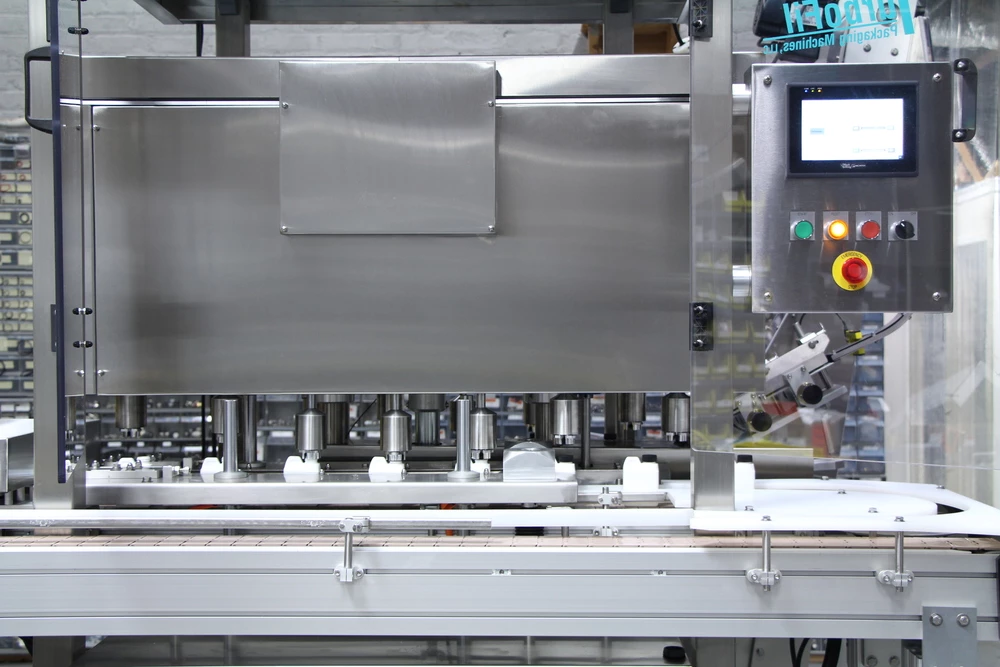

Function: High-speed inline filling system for easy-to-handle bottles; customizable for a wide range of products and viscosities.

Container Designed for stable, free-standing bottles; adaptable for various shapes and sizes.

Output : Processes up to 100 bottles per minute

Material : Low to high viscosity

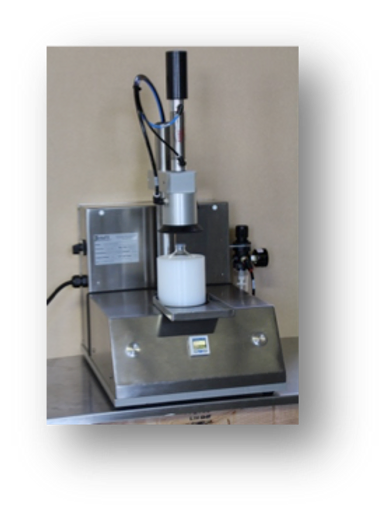

Function: Servo-driven inline capping system that can operate as a fully automatic or semi-automatic solution, mountable to an existing or TurboFil-supplied conveyor.

Container : Ideal for stable bottles; excellent pairing with TurboFil’s UniPuck Adjustable Puck Line.

Output Capacity: Up to 30 bottles per minute

Material : Pneumatic chuck and bottle gripper, stainless steel chute and cap applicator.

Function: Automatic rotary crimper for applying and securing all styles of caps onto stoppered vials with a clean, secure finish.

Container : Designed for vials with pre-inserted stoppers; adaptable to various vial and cap styles.

Output Capacity: Speeds up to 50 vials per minute

Material Handling: Vial fill has no impact

-

Function: Automatic rotary crimper for applying and securing all styles of caps onto stoppered vials with a clean, secure finish.

Container : Designed for perfume vials

Output Capacity: Speeds up to 50 vials per minute

Material Handling: Perfume filled vials

-

Function: High-speed capping system that combines the flexibility of a spindle capper with the precise torque control of a chuck capper for unmatched versatility and accuracy.

Container : No change parts required for bottle variations—simply adjust belt width and capper height

Output : Up to 45 bottles per minute (single head) or up to 80 bottles per minute (dual head)

Material: Fill has no impact

-

Function: High-precision ceramic pump filler designed for accurate filling of syringes and small vials.

-

Container : Suitable for syringes and vials

-

Output : Approximately 20 units per minute

-

Material : Fills hot or cold products

-

Function: Benchtop vacuum filler ideal for short production runs and versatile container types, including those with sprinkler finishes.

Container : Handles rigid glass, metal, and plastic containers

Output : Up to 30 bottles per minute

Material: Suitable for low- to medium-viscosity products

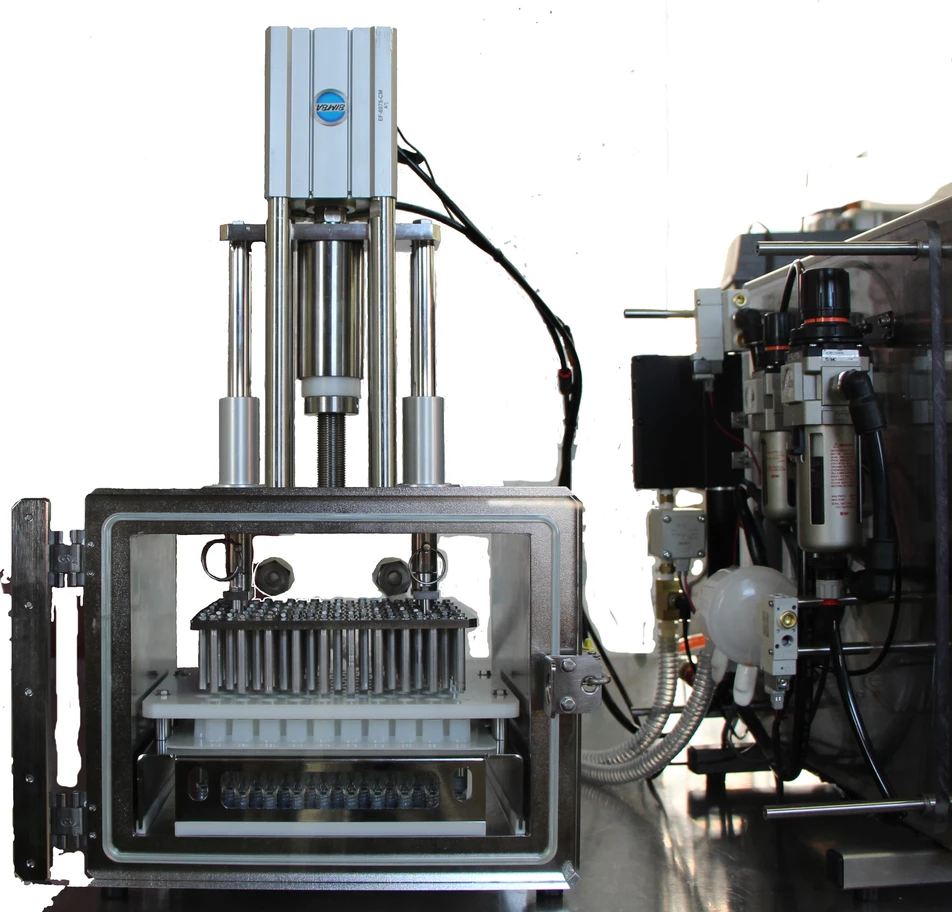

Function: Semi-automatic vacuum chamber for inserting and seating plungers, stoppers, or rods into pre-filled syringes, vials, or tubes.

Container Compatibility: Designed for a wide range of formats; customizable holding fixtures accommodate syringes, vials, or tubes.

Output Capacity: Processes approximately 20 units per minute

Material Handling: Container fill has no impact