TurboFil offers a full line of pharmaceutical vial filling, crimping, capping, & stopper placement machines. Our vial filling & assembly machines can handle a range of production levels, we offer semi-automatic for low volumes, progressing up to automatic machines for higher volumes.

Sterile and non-sterile vial filling is available with the capability of handling both low & high viscosity liquids.

We work directly with our customers to understand their existing vial filling & assembly process allowing us to identify any potential areas of improvement. All our machines are customizable, this enables us to match a vial filling system directly to a customers application.

Automatic Filling and Assembly

Function: Modular, small-footprint system for filling, stoppering, and capping vials ranging from 2ml to 100ml—ideal for clinical trials, pilot runs, and small-batch production.

Container: Handles a wide range of vial sizes with universal format parts

Output: Up to 30 parts per minute

Material : Low to high viscosity

Function: Semi-automatic tray filler for clean room filling of bottles or syringes using servo-controlled XYZ axis for precise dosing.

Container : Supports various tray-based containers including syringes and bottles

Output Suitable for unsupervised, repetitive filling

Material : Handles low to high viscosity liquids

Function: High-performance linear motor-based platform for automated filling and assembly of complex pharmaceutical and cosmetic components.

Container: Customizable for syringes, vials, applicators, & tubes

Output : Up to 120 units per minute

Material : Low to high viscosity

Function: Automated and semi-automated systems for the precise filling and assembly of Aptar UDS (Unidose System) nasal applicators for injectable-free drug delivery.

Container Compatibility: Compatible with single-use UDS applicators

Output Capacity: Up to 80 units per minute standard, with options up to 100 ppm

Material Handling: Inhaled and nasal drug products

Semi-Automatic Filling

Function: Semi-automatic tray filler for clean room filling of bottles or syringes using servo-controlled XYZ axis for precise dosing.

Container : Supports various tray-based containers including syringes and bottles

Output Suitable for unsupervised, repetitive filling

Material : Handles low to high viscosity liquids

Function: Automated and semi-automated systems for the precise filling and assembly of Aptar UDS (Unidose System) nasal applicators for injectable-free drug delivery.

Container Compatibility: Compatible with single-use UDS applicators

Output Capacity: Up to 80 units per minute standard, with options up to 100 ppm

Material Handling: Inhaled and nasal drug products

Crimping

Function: Modular, small-footprint system for filling, stoppering, and capping vials ranging from 2ml to 100ml—ideal for clinical trials, pilot runs, and small-batch production.

Container: Handles a wide range of vial sizes with universal format parts

Output: Up to 30 parts per minute

Material : Low to high viscosity

Function: Universal rotary indexing platform for pacing operators and semi-automated filling and assembly tasks.

Container : Supports various container types and sizes, including irregularly shaped perfume bottles and vials up to 4 oz.

Output : Operator-paced system with optional automation; ideal for short to medium runs and multi-function workflows.

Material :Material has no impact

Function: High-performance linear motor-based platform for automated filling and assembly of complex pharmaceutical and cosmetic components.

Container: Customizable for syringes, vials, applicators, & tubes

Output : Up to 120 units per minute

Material : Low to high viscosity

Function: Automated and semi-automated systems for the precise filling and assembly of Aptar UDS (Unidose System) nasal applicators for injectable-free drug delivery.

Container Compatibility: Compatible with single-use UDS applicators

Output Capacity: Up to 80 units per minute standard, with options up to 100 ppm

Material Handling: Inhaled and nasal drug products

Screw Capping

Function: Modular, small-footprint system for filling, stoppering, and capping vials ranging from 2ml to 100ml—ideal for clinical trials, pilot runs, and small-batch production.

Container: Handles a wide range of vial sizes with universal format parts

Output: Up to 30 parts per minute

Material : Low to high viscosity

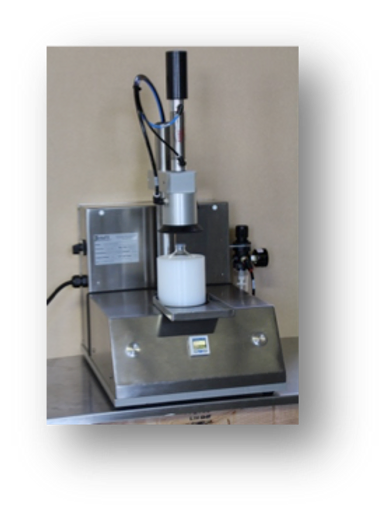

Function: Semi-automatic benchtop vial capping system with hands-free torque control for efficient small-batch processing.

Container : Designed for vials held in Delrin “boats” (10–20 vials per boat depending on size);

Output : Up to 30 vials per minute;

Material : Pharmaceutical, cosmetic, chemical

Stopper Placement

Function: Modular, small-footprint system for filling, stoppering, and capping vials ranging from 2ml to 100ml—ideal for clinical trials, pilot runs, and small-batch production.

Container: Handles a wide range of vial sizes with universal format parts

Output: Up to 30 parts per minute

Material : Low to high viscosity

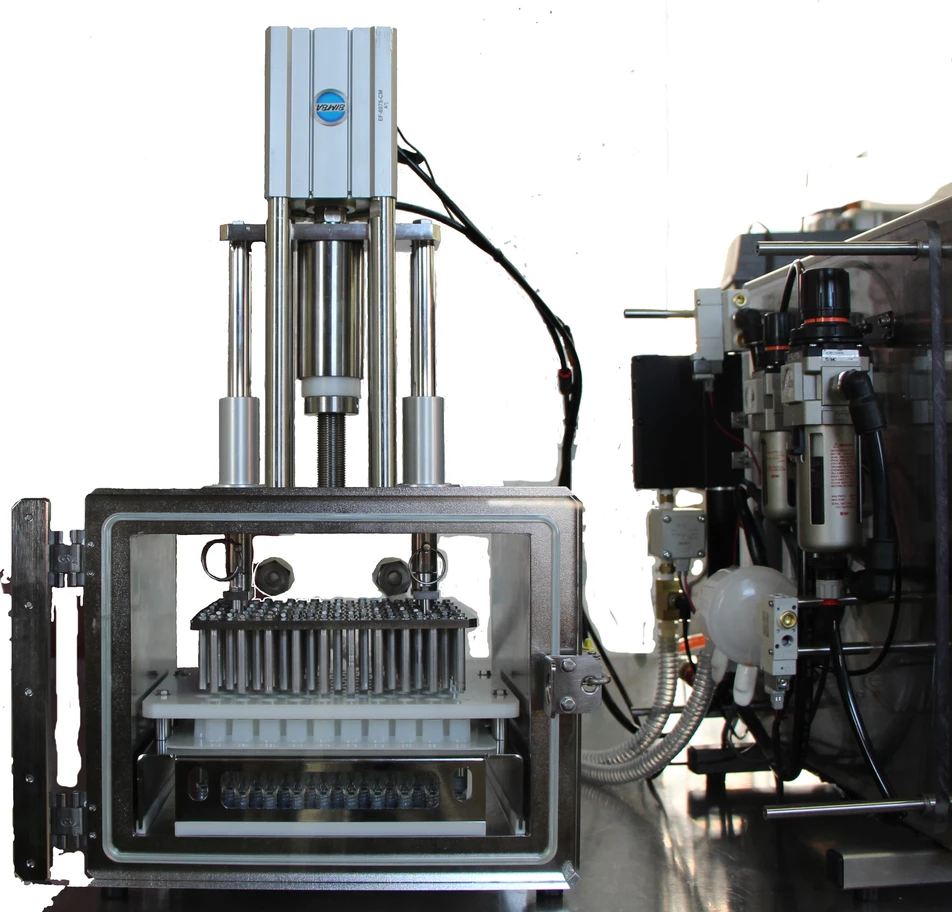

Function: Semi-automatic vacuum chamber for inserting and seating plungers, stoppers, or rods into pre-filled syringes, vials, or tubes.

Container Compatibility: Designed for a wide range of formats; customizable holding fixtures accommodate syringes, vials, or tubes.

Output Capacity: Processes approximately 20 units per minute

Material Handling: Container fill has no impact

Function: Automated vacuum-based system for inserting plungers into single or double-barrel syringes and cartridges.

Container : Designed for filled and capped cartridges or syringes

Output : Up to 15 units per minute

Material: Pharmaceutical and cosmetics

Function: High-performance linear motor-based platform for automated filling and assembly of complex pharmaceutical and cosmetic components.

Container: Customizable for syringes, vials, applicators, & tubes

Output : Up to 120 units per minute

Material : Low to high viscosity

Function: Automated and semi-automated systems for the precise filling and assembly of Aptar UDS (Unidose System) nasal applicators for injectable-free drug delivery.

Container Compatibility: Compatible with single-use UDS applicators

Output Capacity: Up to 80 units per minute standard, with options up to 100 ppm

Material Handling: Inhaled and nasal drug products