-

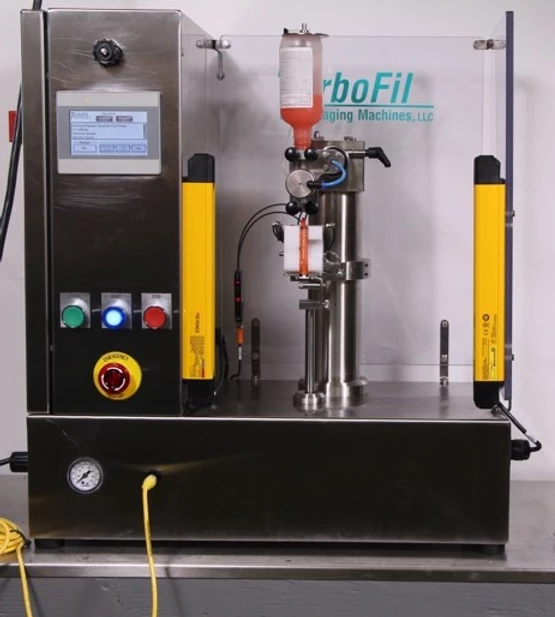

Syringes filled through the tip

-

Liquid filling accuracy +/- 0.5%

-

Suck back nozzle design for drip free operation

-

Can be filled by either direct draw, a peristaltic pump or a piston pump

-

-

TipFil solution for syringes

-

1 to 2 filling heads

-

Liquids and syrups

-

Disposable Path

-

Fill up to 12 syringes per min

-

-

Clean room filler for nested syringes, vials and cartridge

-

Small to intermediate sized batches

-