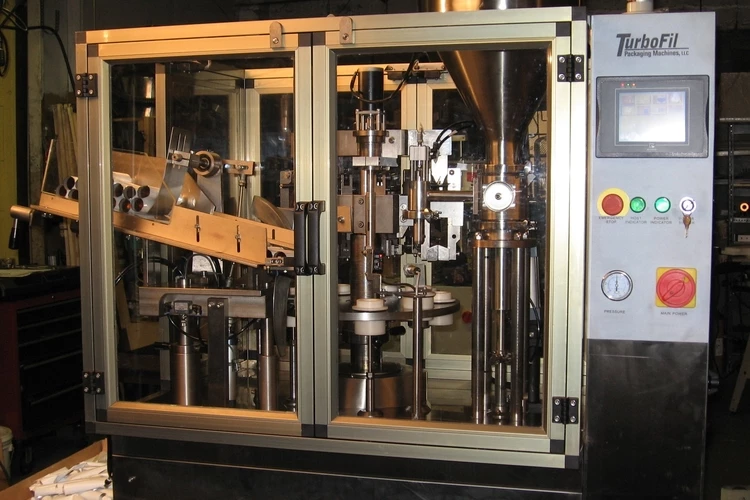

Function: Fully automatic tube filling and sealing system for aluminum, plastic, and laminate tubes with integrated orientation, filling, sealing, and coding.

Container : Supports metal, plastic, or laminate tubes

Output : Up to 40 tubes/min (plastic/laminate), up to 60 tubes/min (metal tubes), depending on size and tube material.

Material Handling: Low to high viscosity

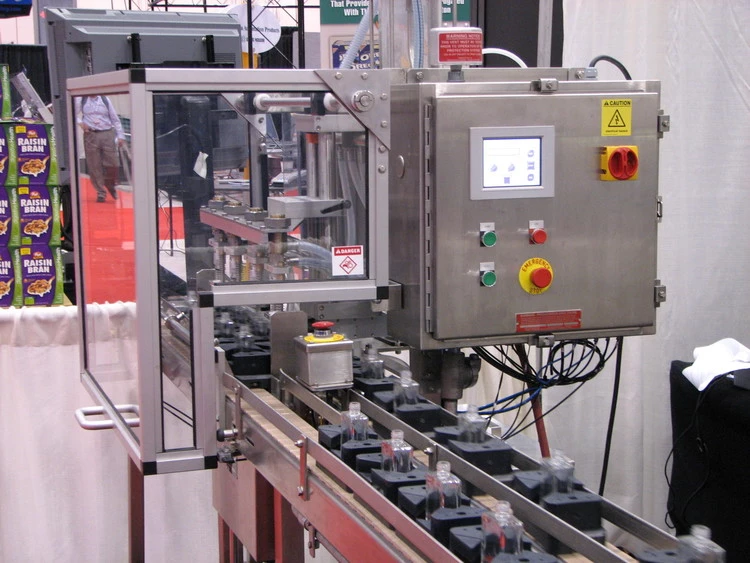

Function: Inline filling and closing system using adjustable pucks for rapid changeover between various bottle shapes and sizes—no change parts required.

Container : Handles a wide range of glass or plastic bottles, vials, or jars

Output : Up to 60 units per minute

Material : suitable for perfumes, lotions, creams, and more.

Function: Semi-automatic benchtop vial capping system with hands-free torque control for efficient small-batch processing.

Container : Designed for vials held in Delrin “boats” (10–20 vials per boat depending on size);

Output : Up to 30 vials per minute;

Material : Pharmaceutical, cosmetic, chemical

Function: Universal rotary indexing platform for pacing operators and semi-automated filling and assembly tasks.

Container : Supports various container types and sizes, including irregularly shaped perfume bottles and vials up to 4 oz.

Output : Operator-paced system with optional automation; ideal for short to medium runs and multi-function workflows.

Material :Material has no impact

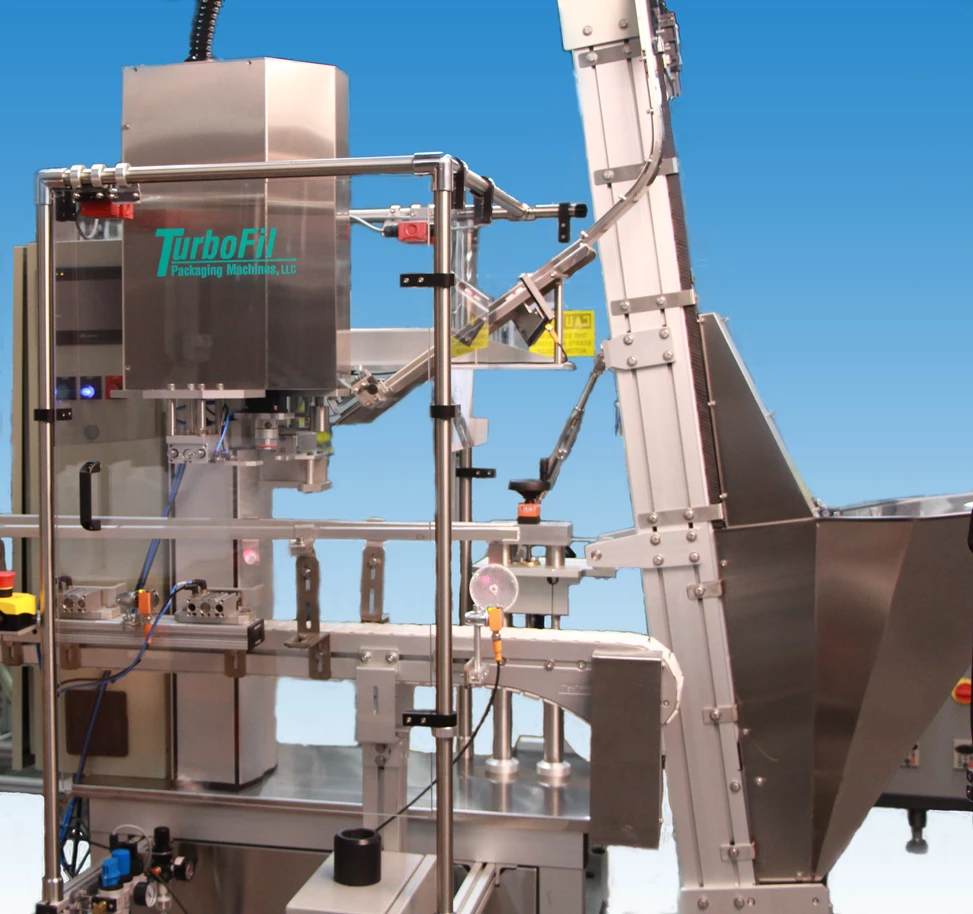

Function: Servo-driven inline capping system that can operate as a fully automatic or semi-automatic solution, mountable to an existing or TurboFil-supplied conveyor.

Container : Ideal for stable bottles; excellent pairing with TurboFil’s UniPuck Adjustable Puck Line.

Output Capacity: Up to 30 bottles per minute

Material : Pneumatic chuck and bottle gripper, stainless steel chute and cap applicator.

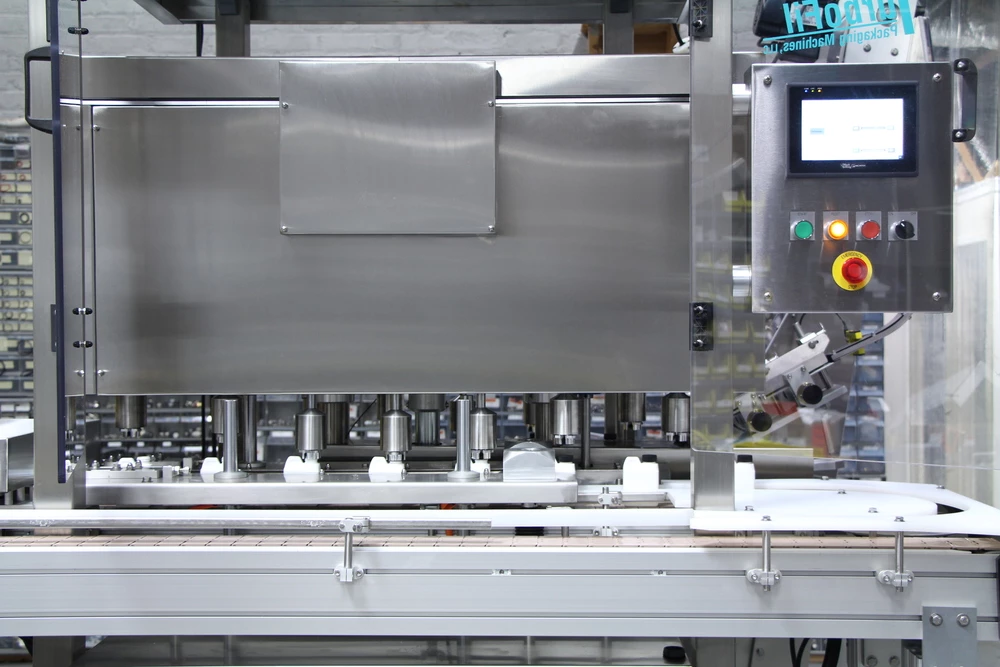

Function: High-speed capping system that combines the flexibility of a spindle capper with the precise torque control of a chuck capper for unmatched versatility and accuracy.

Container : No change parts required for bottle variations—simply adjust belt width and capper height

Output : Up to 45 bottles per minute (single head) or up to 80 bottles per minute (dual head)

Material: Fill has no impact

-

Function: High-precision ceramic pump filler designed for accurate filling of syringes and small vials.

-

Container : Suitable for syringes and vials

-

Output : Approximately 20 units per minute

-

Material : Fills hot or cold products

-

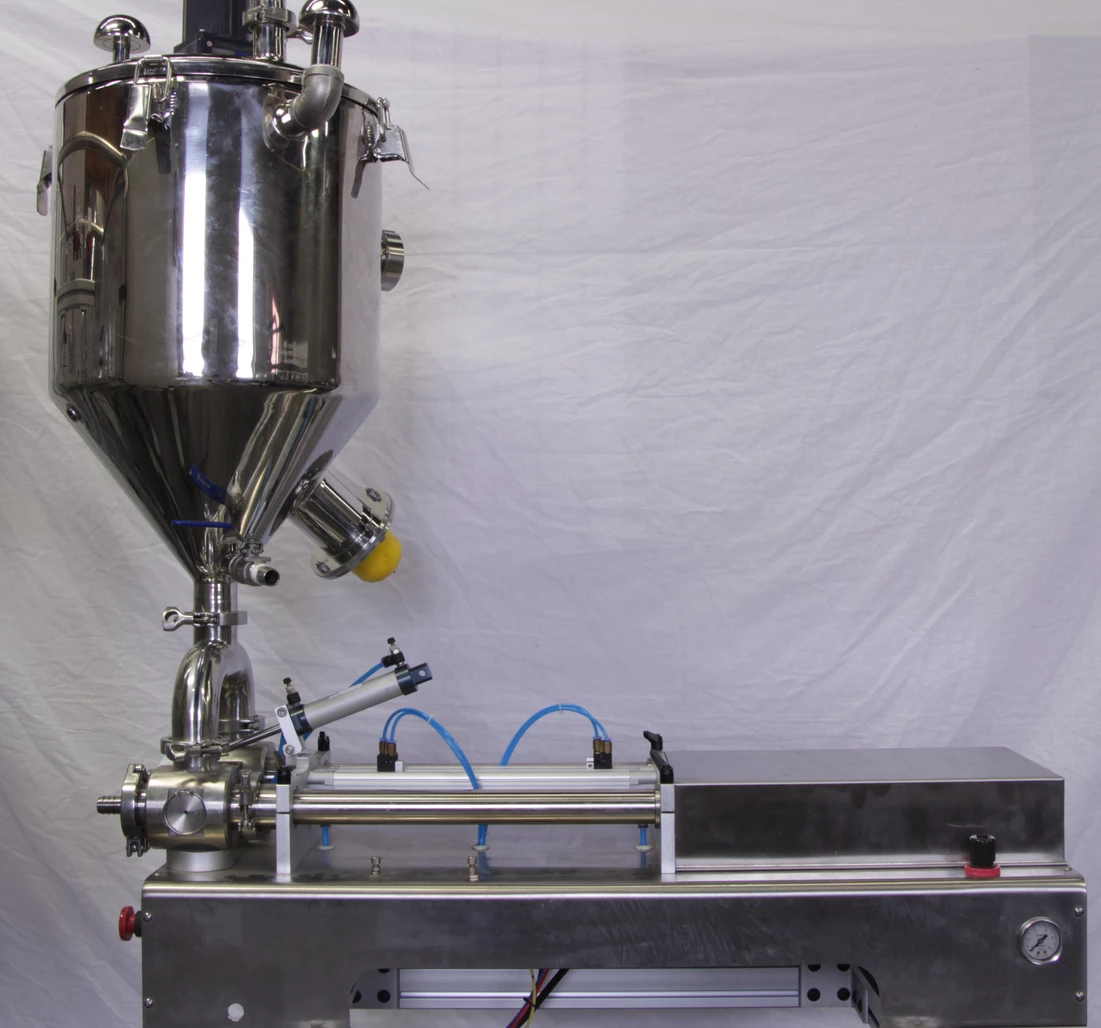

Function: Semi-automatic piston filler designed for high-volume filling of liquids, creams, and viscous products.

Container : Supports a wide fill range of vials and syringes

Output : Up to 20 cycles per minute

Material : liquids, creams, and viscous products.