TurboFil offers solutions for small parts, medical devices, and o-ring assembly. These solutions can be integrated into existing systems allowing for accurate and reliable results. Our engineers are experts in factory automation and can develop a turnkey system to fit your companies needs.

-

Standard web width up to 5″

-

Portable and lightweight table top unit

-

Label application activated by foot switch

-

-

Standard web width up to 5″

-

Portable and lightweight table top unit

-

Label application activated by foot switch

-

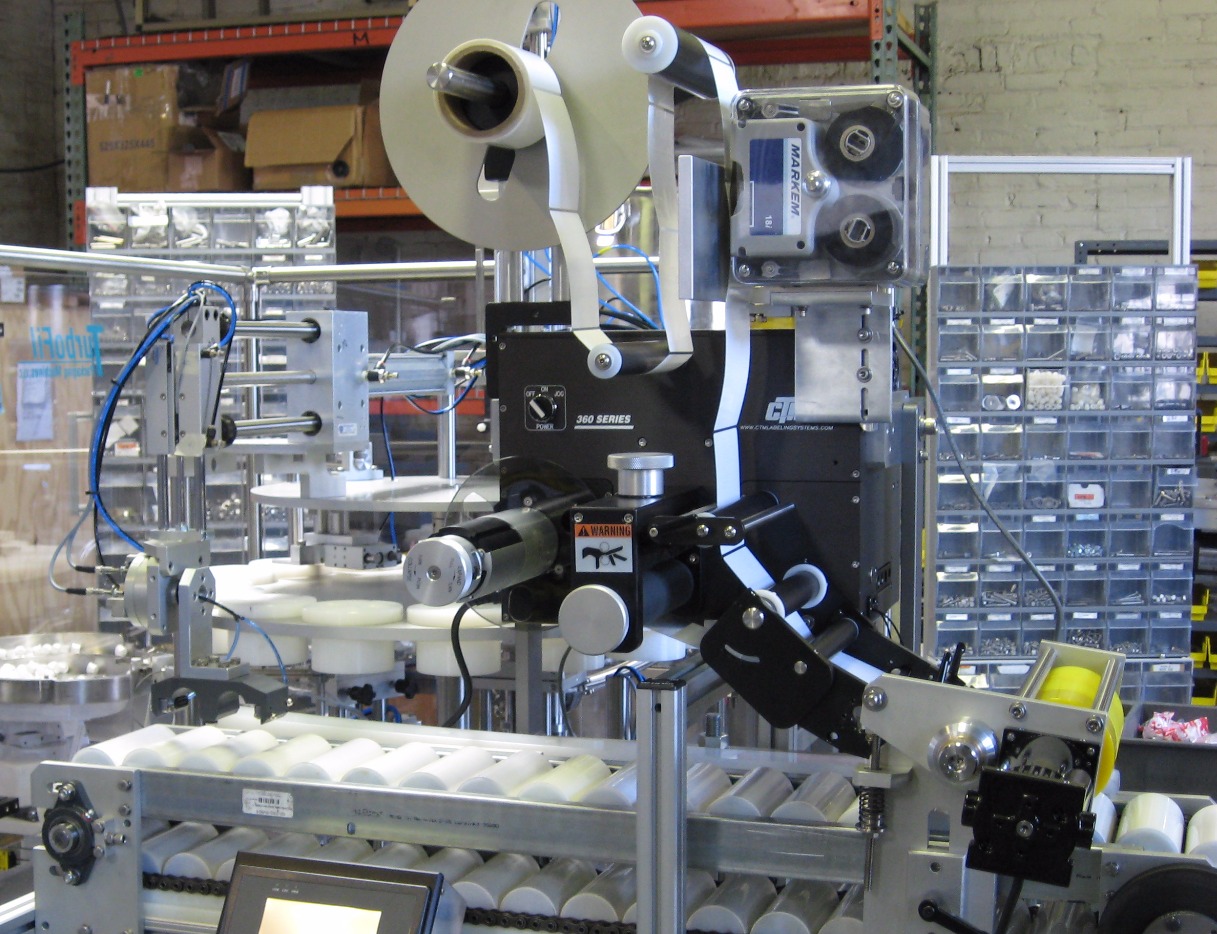

Function: High-precision inline labeling system designed specifically for dual chamber syringes, ensuring accurate and consistent label placement.

Container : Accommodates a wide range of dual chamber syringes

Material : Applies both paper and plastic labels with high positional accuracy.

Output Capacity: 30 parts per minute

Function: Automated and semi-automated systems for the precise filling and assembly of Aptar UDS (Unidose System) nasal applicators for injectable-free drug delivery.

Container Compatibility: Compatible with single-use UDS applicators

Output Capacity: Up to 80 units per minute standard, with options up to 100 ppm

Material Handling: Inhaled and nasal drug products

Function: High-performance linear motor-based platform for automated filling and assembly of complex pharmaceutical and cosmetic components.

Container: Customizable for syringes, vials, applicators, & tubes

Output : Up to 120 units per minute

Material : Low to high viscosity

Function: Automated vacuum-based system for inserting plungers into single or double-barrel syringes and cartridges.

Container : Designed for filled and capped cartridges or syringes

Output : Up to 15 units per minute

Material: Pharmaceutical and cosmetics

Function: Automated syringe filling and capping system using TurboFil’s TipFil technology for filling through the syringe tip.

Container : Works with pre-assembled syringes

Output : Up to 25 parts per minute

Material : Low to high viscosity

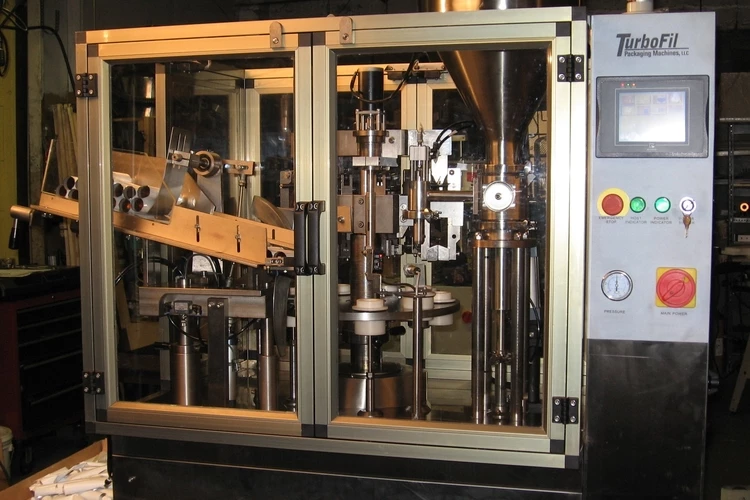

Function: Fully automatic tube filling and sealing system for aluminum, plastic, and laminate tubes with integrated orientation, filling, sealing, and coding.

Container : Supports metal, plastic, or laminate tubes

Output : Up to 40 tubes/min (plastic/laminate), up to 60 tubes/min (metal tubes), depending on size and tube material.

Material Handling: Low to high viscosity

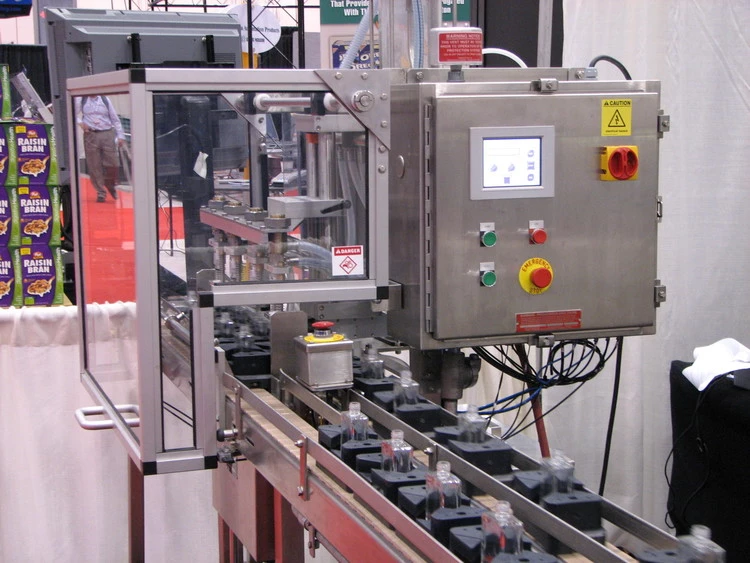

Function: Inline filling and closing system using adjustable pucks for rapid changeover between various bottle shapes and sizes—no change parts required.

Container : Handles a wide range of glass or plastic bottles, vials, or jars

Output : Up to 60 units per minute

Material : suitable for perfumes, lotions, creams, and more.