TurboFils syringe and cartridge filling and assembly machines are for a range of production rates. Automatic filling machines allow for minimal operator involvement as well as high rates of production. Semi-automatic filling machines have a smaller footprint and a lower fill rate.

TurboFil syringe and cartridge filling machines can accommodate both high and low viscosity liquids, as well as other difficult to handle materials.

Function: High-performance linear motor-based platform for automated filling and assembly of complex pharmaceutical and cosmetic components.

Container: Customizable for syringes, vials, applicators, & tubes

Output : Up to 120 units per minute

Material : Low to high viscosity

Function: Automated syringe filling and capping system using TurboFil’s TipFil technology for filling through the syringe tip.

Container : Works with pre-assembled syringes

Output : Up to 25 parts per minute

Material : Low to high viscosity

Function: High-speed inline filling system for easy-to-handle bottles; customizable for a wide range of products and viscosities.

Container Designed for stable, free-standing bottles; adaptable for various shapes and sizes.

Output : Processes up to 100 bottles per minute

Material : Low to high viscosity

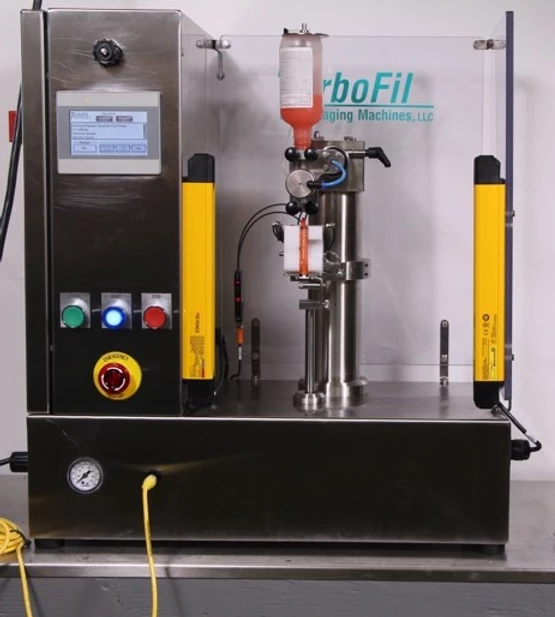

Function: Semi-automatic bench-top system for precise syringe filling using a servo-controlled plunger draw

Container : Designed specifically for syringes with inserted plungers

Output: Up to 12 syringes per minute

Material : Fully disposable fluid path; low viscosity fluids

Function: Semi-automatic tray filler for clean room filling of bottles or syringes using servo-controlled XYZ axis for precise dosing.

Container : Supports various tray-based containers including syringes and bottles

Output Suitable for unsupervised, repetitive filling

Material : Handles low to high viscosity liquids