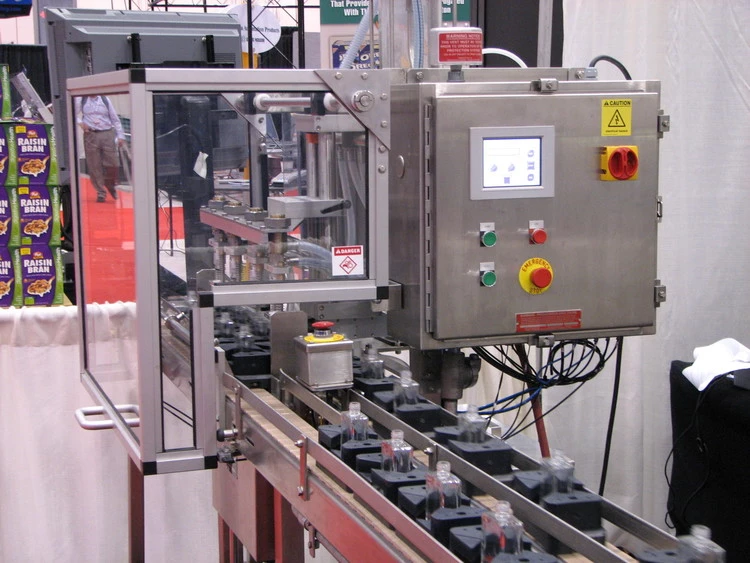

Function: Inline filling and closing system using adjustable pucks for rapid changeover between various bottle shapes and sizes—no change parts required.

Container : Handles a wide range of glass or plastic bottles, vials, or jars

Output : Up to 60 units per minute

Material : suitable for perfumes, lotions, creams, and more.

-

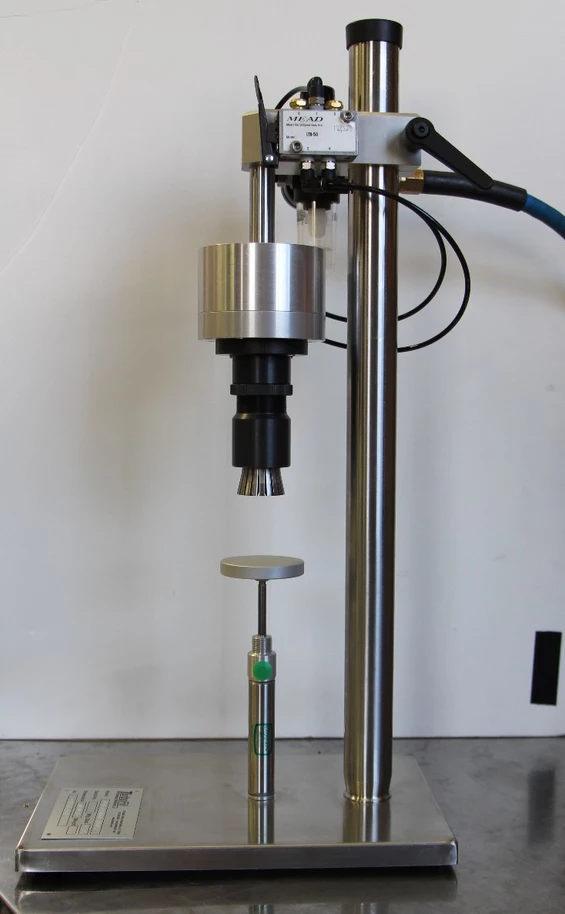

Function: Automatic pneumatic tamper for seating valves, decorative collars, or overcaps onto perfume bottles.

-

Container: Designed for perfume bottles; compatible with various collar and cap styles.

-

Output : Speed-matched to IC-60 crimper; suitable for continuous or batch operations.

-

Material : Available with automatic loading for collars or caps to streamline assembly

-

Function: High-speed inline filling system for easy-to-handle bottles; customizable for a wide range of products and viscosities.

Container Designed for stable, free-standing bottles; adaptable for various shapes and sizes.

Output : Processes up to 100 bottles per minute

Material : Low to high viscosity

-

Function: Automatic rotary crimper for applying and securing all styles of caps onto stoppered vials with a clean, secure finish.

Container : Designed for perfume vials

Output Capacity: Speeds up to 50 vials per minute

Material Handling: Perfume filled vials

-

Function: Benchtop vacuum filler ideal for short production runs and versatile container types, including those with sprinkler finishes.

Container : Handles rigid glass, metal, and plastic containers

Output : Up to 30 bottles per minute

Material: Suitable for low- to medium-viscosity products

-

Pneumatic crimper for low to moderate volume perfume crimping jobs

-

Fast, accurate, reliable and cost effective solution

-