TurboFil automatic capping machines are for high speed capping of containers filled with pharmaceuticals, cosmetics, and chemicals.These machines will quickly and precisely marry your caps and lids to filled containers and return them to your packaging line conveyor for downstream operations.

Function: Compact tabletop monoblock system for automatic filling and capping or crimping of small bottles and vials—no conveyor required.

Container : Supports glass or plastic bottles and vials

Output: 15–40 units per minute

Material : Low to high viscosity liquids

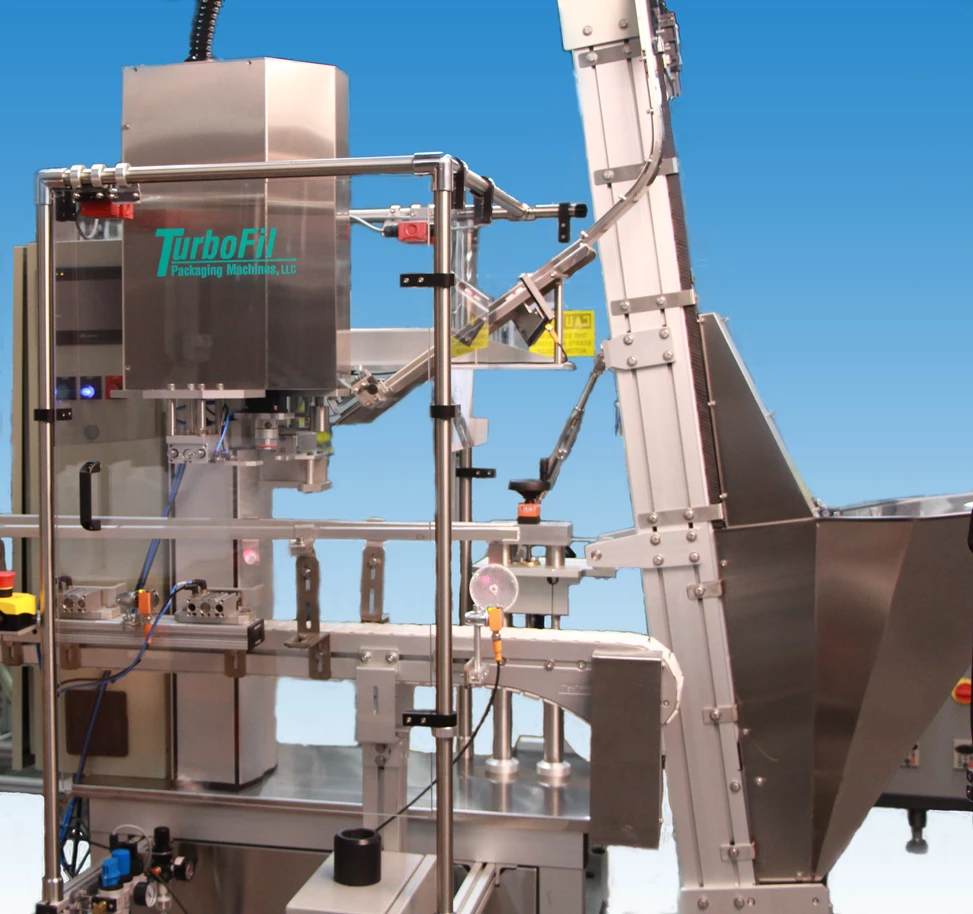

Function: Servo-driven inline capping system that can operate as a fully automatic or semi-automatic solution, mountable to an existing or TurboFil-supplied conveyor.

Container : Ideal for stable bottles; excellent pairing with TurboFil’s UniPuck Adjustable Puck Line.

Output Capacity: Up to 30 bottles per minute

Material : Pneumatic chuck and bottle gripper, stainless steel chute and cap applicator.

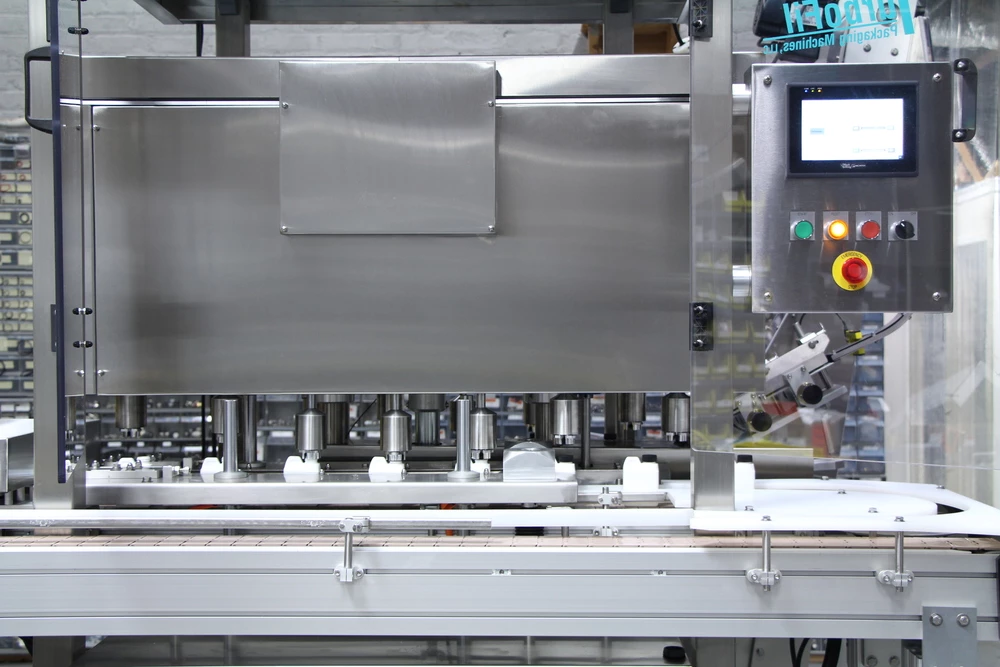

Function: High-speed capping system that combines the flexibility of a spindle capper with the precise torque control of a chuck capper for unmatched versatility and accuracy.

Container : No change parts required for bottle variations—simply adjust belt width and capper height

Output : Up to 45 bottles per minute (single head) or up to 80 bottles per minute (dual head)

Material: Fill has no impact