TurboFil offers solutions for small parts, medical devices, and o-ring assembly. These solutions can be integrated into existing systems allowing for accurate and reliable results. Our engineers are experts in factory automation and can develop a turnkey system to fit your companies needs.

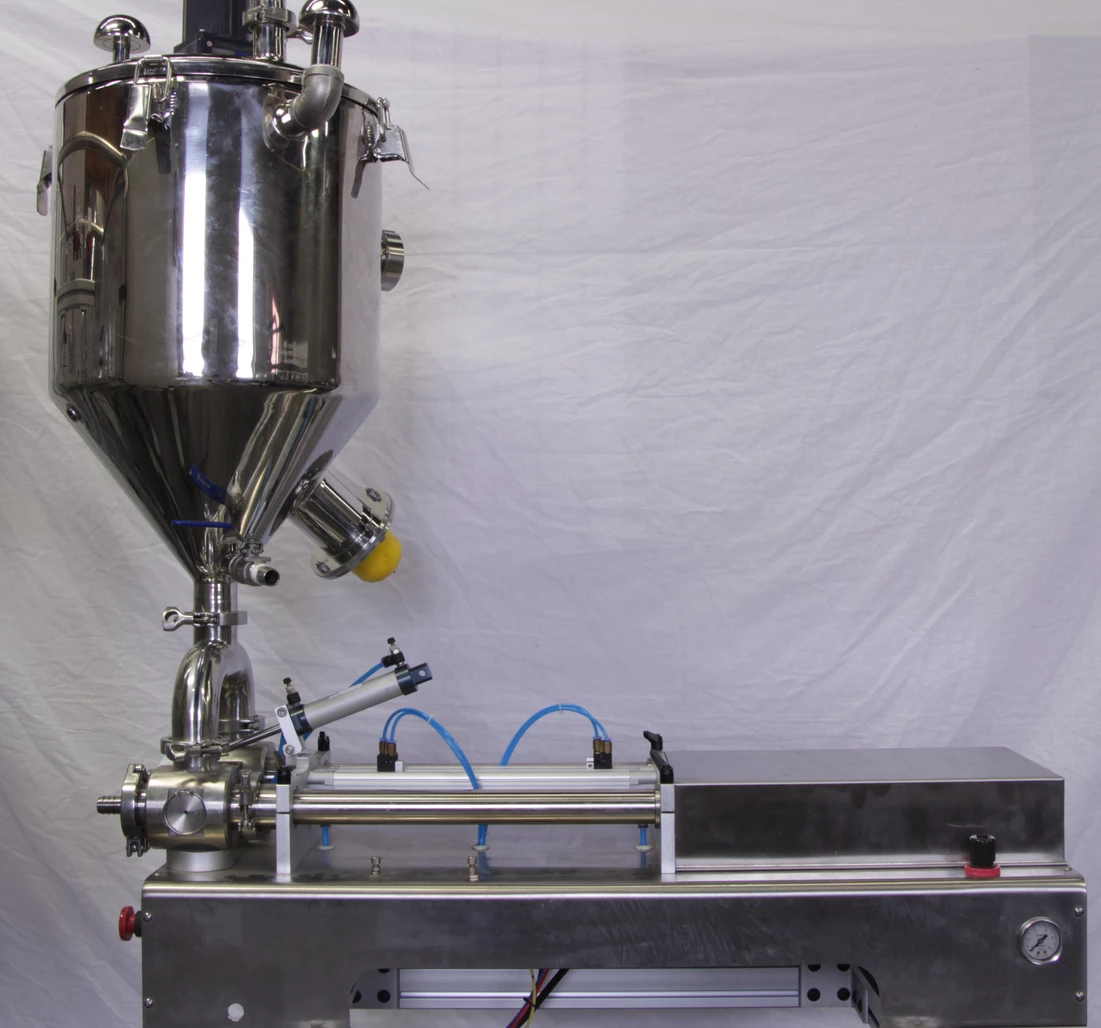

Function: Semi-automatic piston filler designed for high-volume filling of liquids, creams, and viscous products.

Container : Supports a wide fill range of vials and syringes

Output : Up to 20 cycles per minute

Material : liquids, creams, and viscous products.

-

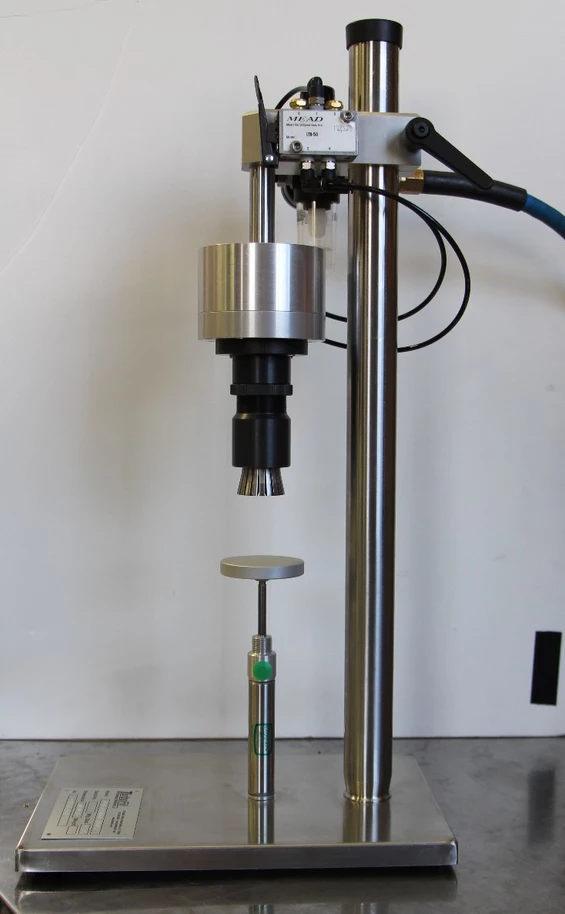

Pneumatic crimper for low to moderate volume vial crimping jobs

-

Fast, accurate, reliable and cost effective solution

-

-

Pneumatic crimper for low to moderate volume perfume crimping jobs

-

Fast, accurate, reliable and cost effective solution

-

Function: Semi-automatic bench-top system for precise syringe filling using a servo-controlled plunger draw

Container : Designed specifically for syringes with inserted plungers

Output: Up to 12 syringes per minute

Material : Fully disposable fluid path; low viscosity fluids

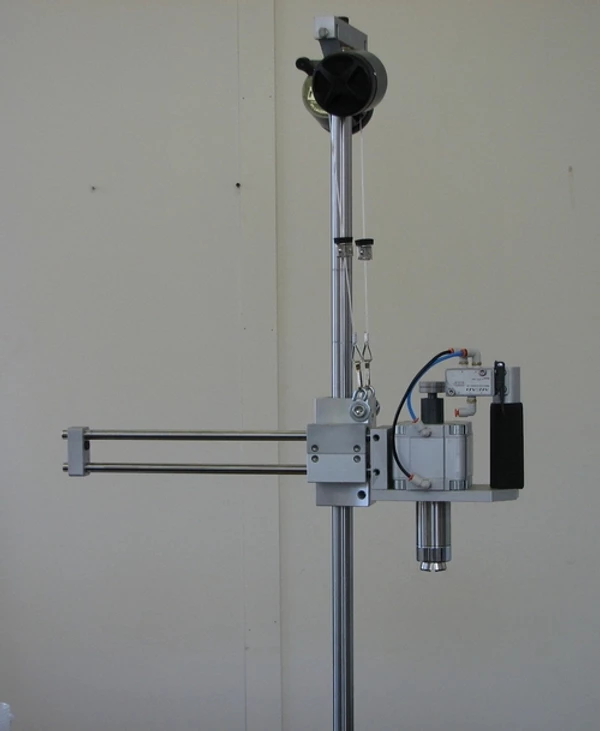

Function: Semi-automatic tray filler for clean room filling of bottles or syringes using servo-controlled XYZ axis for precise dosing.

Container : Supports various tray-based containers including syringes and bottles

Output Suitable for unsupervised, repetitive filling

Material : Handles low to high viscosity liquids

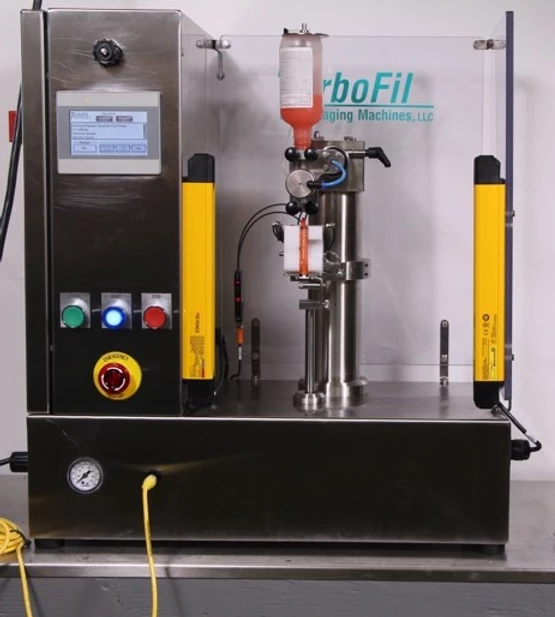

Function: Modular, small-footprint system for filling, stoppering, and capping vials ranging from 2ml to 100ml—ideal for clinical trials, pilot runs, and small-batch production.

Container: Handles a wide range of vial sizes with universal format parts

Output: Up to 30 parts per minute

Material : Low to high viscosity