Function: Universal rotary indexing platform for pacing operators and semi-automated filling and assembly tasks.

Container : Supports various container types and sizes, including irregularly shaped perfume bottles and vials up to 4 oz.

Output : Operator-paced system with optional automation; ideal for short to medium runs and multi-function workflows.

Material :Material has no impact

- Function: Bench-top volumetric piston filler designed for precise filling

-

Container : Ideal for small cosmetic containers; fill range from 7–30ml.

-

Output : Up to 20 cycles per minute

-

Material: Handles a wide range of viscosities

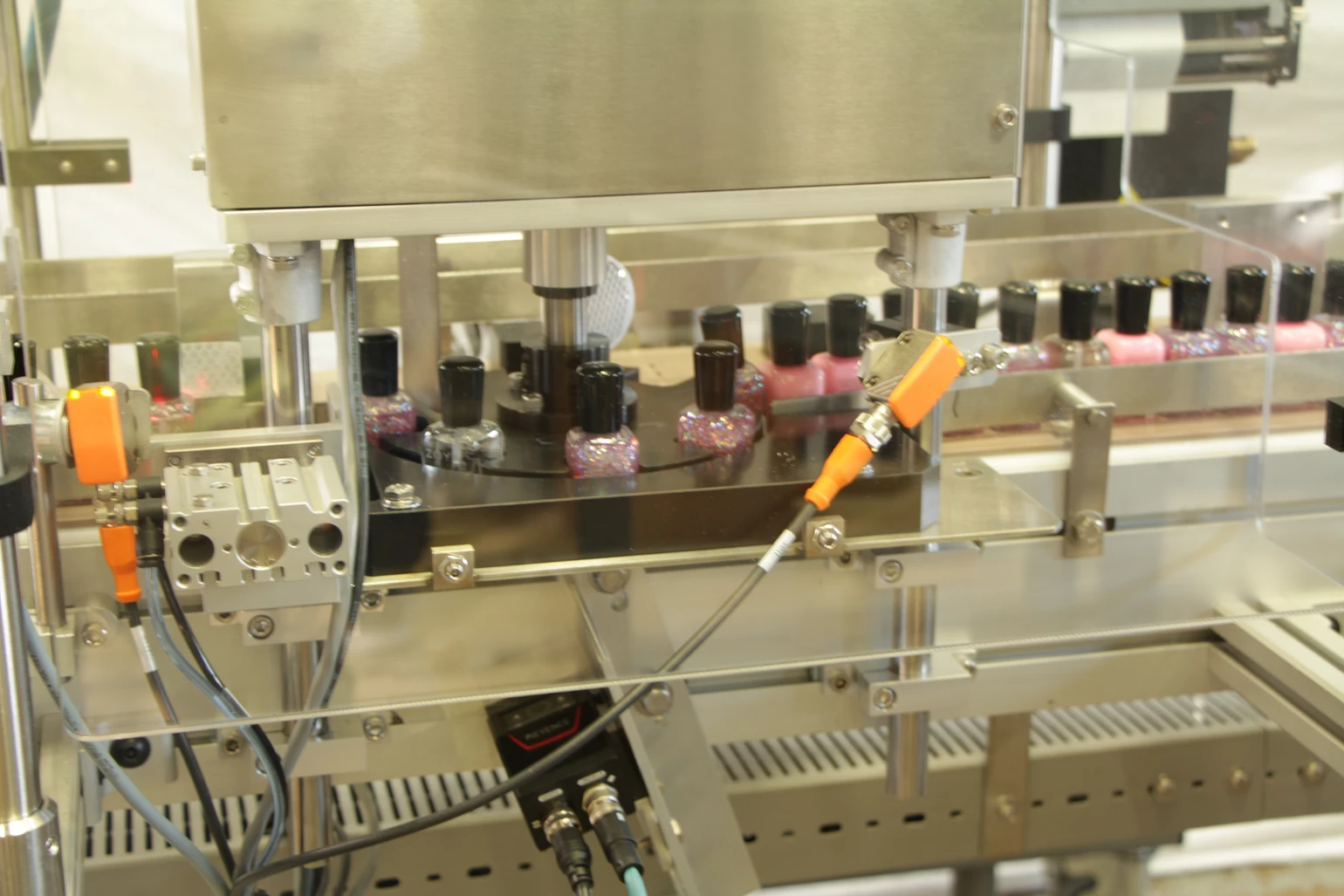

Function: Inline piston filling system designed for nail polish and treatment products, including challenging formulas like gels, glitters, and micas.

Container : Suitable for various nail polish bottle shapes and sizes

Output : 60 parts per minute

Material : Nail polish

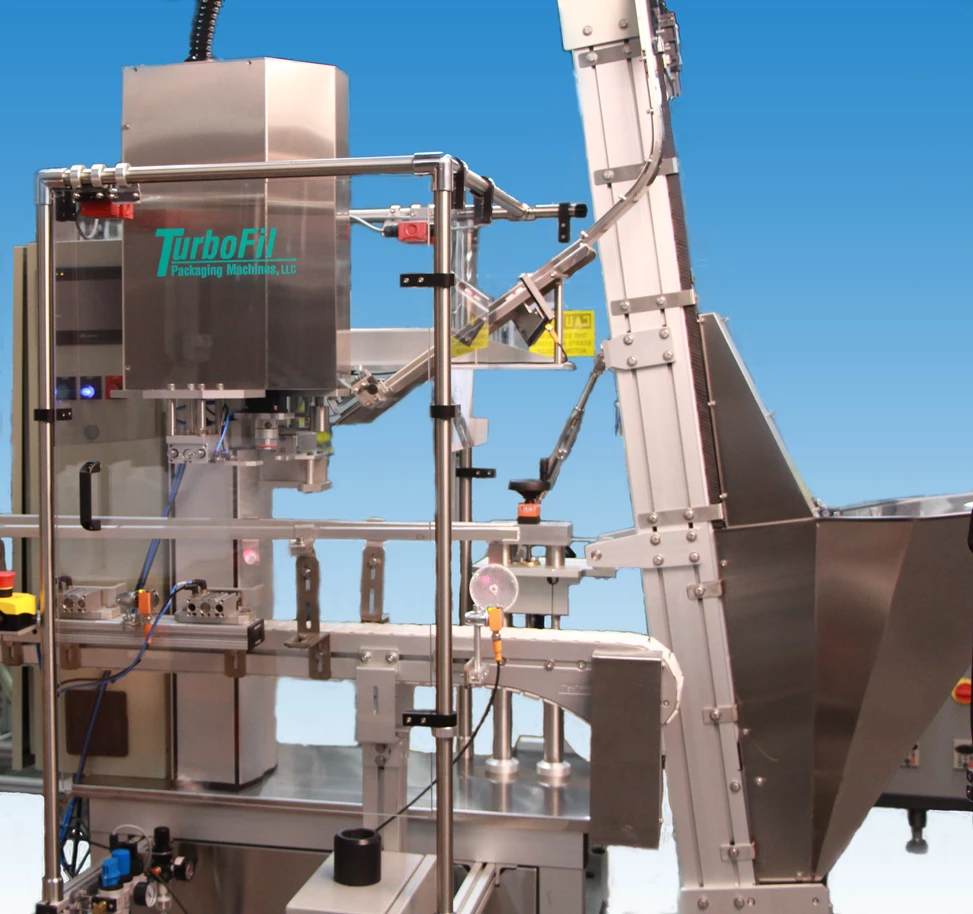

Function: High-speed monoblock system for fully automatic filling, brush/cap insertion, BB dropping, and torquing of nail polish bottles.

Container Compatibility: Supports round, square, oval, rectangular, tapered, and irregular bottle shapes with various closure types (brush, cap, brush-cap combo).

Output Capacity: Up to 55 bottles/min (single index) or up to 100 pieces/min (dual index)

Material Handling: Nail polish

Function: Servo-driven inline capping system that can operate as a fully automatic or semi-automatic solution, mountable to an existing or TurboFil-supplied conveyor.

Container : Ideal for stable bottles; excellent pairing with TurboFil’s UniPuck Adjustable Puck Line.

Output Capacity: Up to 30 bottles per minute

Material : Pneumatic chuck and bottle gripper, stainless steel chute and cap applicator.