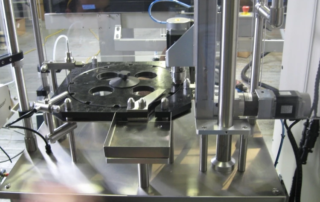

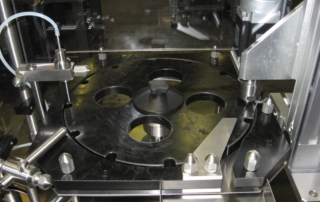

This is TurboFil’s semi-automated rotary indexing workstation. It is a universal indexing machine that you can use to pace your operators. We can include a variety of automatic filling and assembly functions, according to your needs.

The rotary configuration offers a significant logistical advantage over in-line operation because of the minimal space required. In addition, you can achieve multiple functions with a minimum of manual labor…and it serves to pace the operators, as well.

The workstation has also been configured for numerous applications in pharmaceuticals and cosmetics. For example, in perfume filling and crimping, it is able to accommodate odd shaped bottles with irregular bases (accomplished by the use of holding pucks that orient the neck of the bottle).

You can fill anywhere between a few mls. (sample perfume vials) up to 4 oz. bottles or more. Changeover between bottles is completed in a matter of minutes. The machine can be ordered explosion proof.

As with all TurboFil machines, this is a reliable and efficient workhorse for your operation.

-

Can be customized to meet your specific needs

Features

-

Power On-Off switch/circuit breaker.

-

Machine Stop and Start function key.

-

PLC machine controller (Allen Bradley)

-

7” Color touchscreen HMI (Maple Systems)

-

Vial presence sensor

-

Fill verification sensor

-

Emergency Stop switch.

-

Ethernet capability for remote diagnostics

Options

-

Can be ordered explosion proof

Key Benefits

-

Flexible: Can use any of a variety of filling technologies, from vacuum to volumetric or peristaltic (among others)

-

Modular: Multiple functions, multiple components. We can add or remove functions depending on your particular needs

-

Cost effective: For the budget minded business

-

Small footprint: Minimal space consumption. Use in areas where a larger machine would not be convenient