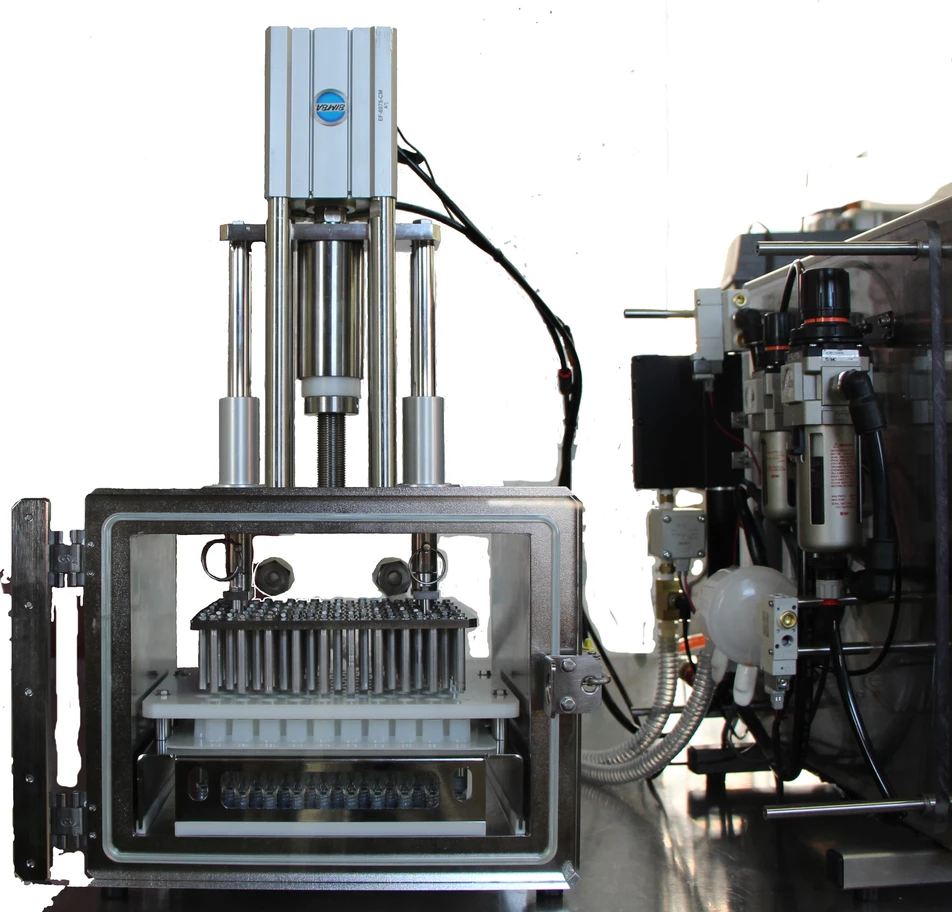

TurboFil’s Benchtop Vacuum Chamber can be used to insert and seat stoppers or plunger rods into pre-filled syringes, vials or tubes.

The Vacuum Seater consists of a stainless steel vacuum chamber with an air-driven seating plate and a control box. The operator puts the loaded syringe rack into the chamber. The vacuum is reached and the stoppers are pressed into place.

The chamber is constructed of stainless steel with a high gloss finish. The control box can be separated from the chamber itself making this unit particularly suitable for use inside a laminar flow hood.

Because of TurboFil’s deep design expertise, this system can be fully customized to the requirements of your application

Features

-

Holding fixtures for a wide range of formats

-

Piston seating accomplished by a combination of vacuum and adjustable stroke plunger insertion

-

Foot-switch for activation

-

Adjustable timer for vacuum hold before seating piston

-

Air operated vacuum generator up to 29Hg

-

Vacuum sensor

-

316 stainless steel interior surface with #4 polish finish

-

Welded box frame

-

Polycarbonate clear door with lock

-

Color HMI operator interface

-

PLC controlled

-

Validation package available

Speed : Approximately 20 per minute

Specifications

-

Dimensions (chamber): 13” x 16” x 25″

-

Weight: Approx 70 lbs

-

Electric: 110V, 2 AMP (220V available)

Key Benefits

-

Very easy to use

-

Cost-effective